Drywall Vs. Blueboard: What's The Difference?

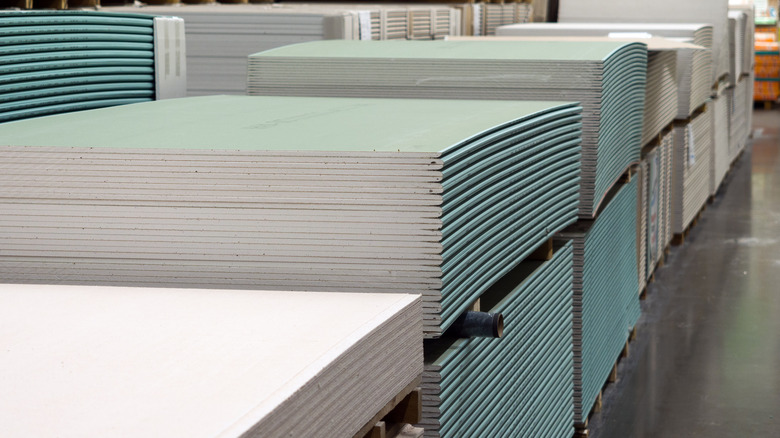

According to eSUB Construction Software, there are actually several colors of drywall, including green and purple, as well as a blueboard version. Interestingly, there's also paperless drywall and cement board. But in this article, we'll be discussing the difference between regular drywall and blueboard. Are you a DIYer doing your own home renovations, or are you having something built and trying to decide what materials to use? With all of these choices, how do you know what to pick?

Most people are familiar with drywall, but this knowledge may only be that the walls of a home are made out of it. But when you're in a position where you need to know what kind of drywall is best, you might want to know a little more about the options. That's of course where we come in, always willing to help with a deep dive into the subject at hand!

What are the uses of drywall?

When most people think of drywall, they think of walls and ceilings, right? Absolutely, but it has more uses than that. According to Paint City, drywall is a versatile material. For example, you can use it to create architectural elements in a builder-grade room, such as installing arches between areas for a subtle touch of class. Or perhaps you'd like to put a couple of niches into a living room wall, with some recessed lighting to highlight objects displayed within. This helps any new build home stand out more.

While the material is common in new construction, drywall can be especially helpful when improving rooms in an existing property. It's the primary material for renovations like finishing basements or attics, per Budget Dumpster. It helps you hide the exposed framework by putting up finished walls and ceilings, and divides the space by building walls to create rooms. Just make sure to research what kind of material is best for the space. Areas like attics and basements can typically benefit from using moisture-resistant drywall sheets.

What are the uses of blueboard?

While blueboard is a type of drywall, it has a specific, intended purpose when basic drywall isn't sufficient for a project. These types of boards are also often referred to as plaster baseboard. That's because they create the ideal foundation for a veneer plaster wall finish. The blue paper is designed to bond with plastering, according to the Home Efficiency Guide. Some people choose to plaster their walls because it not only helps hide imperfections and creates a smooth base for paint, but also makes the wall more durable.

Blueboard is also considered more durable than regular drywall and has soundproofing and mold-resistance qualities. Because of that, you can choose to include it in specific areas of the house that would benefit from those features. For example, some people choose to use plaster and blueboard to insulate and soundproof a studio or a home office. This material is great for painting, as well as providing a better quality finish. It's impact-resistant leading to a longer lifespan, surpassing drywall in performance on many levels.

What is drywall made out of?

According to Angi, drywall is also known as gypsum board as the mineral makes up a large portion of the material. The drywall manufacturing process has multiple steps and either mined gypsum or a synthetic form can be used (via Gypsum Association). The gypsum is ground into a powder known as calcium sulfate and is heated to remove moisture.

When it's time to pour the boards, water and additives like resin are added to the dry mixture. This produces a spreadable substance called a slurry. A machine layers this mixture between large sheets of paper until it forms a board of the desired thickness. When exposed to the air, the layers of slurry crystalize and bond with the paper, creating a solid surface.

After the board is cut and dried, branded and labeled tape is applied to the edges to make sheets of drywall that are ready for purchase. The powder that's produced when you cut or break drywall is actually gypsum dust. It's relatively safe but can irritate respiratory systems so it's a good idea to use protective gear when drywalling.

What is blueboard made out of?

As Hunker points out, blueboard is made of gypsum like other types of drywall. However, typical drywall is intended to serve as a primary. standalone wall surface. Blueboard was developed to revamp the tedious plaster wall-building process. These boards were made with a dense core and namesake blue paper to create the ideal surface for plaster veneer to adhere to. With this innovation, builders could produce the durability of plaster walls more efficiently.

When used as part of a veneer plastering system, the composition of blueboards provides some helpful benefits. The finished surface is both moisture and mold-resistant, making it ideal for bathrooms and kitchens (via eSUB). The boards also provide a noise-reducing base layer that, when combined with layered plaster, softens echoes and reduces sound pollution in spaces like basements. Plus, given its extreme durability, it's a perfect option for playrooms and home gyms.

Pros and cons of drywall

One big advantage of drywall is that it's cost-effective and readily available, thanks to the streamlined manufacturing process (via Quarts Drywall and Painting). It's easy to patch or repair and can be used inside safely for walls and ceilings. The material is ideal for patching large wall holes and can be easily cut for future projects like lighting installations. It is fire-resistant and less expensive than other options. Though challenging, regular drywall is an easier DIY project than blueboard plastering. Additionally, regular drywall is faster drying than plaster, which takes about a month to completely dry (via Unique Painting KC).

On the flip side, drywall is not very durable, and is heavy and difficult to hang without damaging it. It is not typically water-resistant, so enhanced versions that resist moisture must be used in areas like bathrooms and damp basements. It's not impact-resistant either and damage is often sustained and it will need to be patched and replaced in those spots. Drywall is also a messy installation process that comes with lots of dust and a tedious finishing process.

Pros and cons of blueboard

According to DoItYourself, blueboard allows for complete customization. The blue paper is designed for adhesion, so it's the perfect surface for a variety of coatings, including regular paint. Blueboard doesn't require the same tedious, multi-step finishing process as drywall, so once hung, it can be painted without even needing to be primed. When layering blueboard with plaster, specially-formulated paints can be added to the mixture, giving the surface a finished look when it dries.

However, the one major drawback of blueboard is the higher price point of the materials and the more expensive process overall. Blueboards can be priced about 20 percent higher than typical value drywall panels. The special plaster needed for the veneer process is also more expensive than drywall finishing compound. Plus, the process of using blueboard and plastering requires high-level skills. If you don't have the know-how to execute the process properly, you could end up ruining materials. Otherwise, you'll need to hire a contractor and incur that additional cost.

What are the cost differences?

According to HomeGuide, you can buy standard drywall for about $8 to $20 per panel. The exact price point varies depending on factors like the thickness, the manufacturer, and the quality of the board. It's also important to note that you can get multiple different types of drywall that improve various aspects of its disadvantages. You can purchase soundproof drywall boards and those that are resistant to fire or moisture, but these features come at a higher price. When hanging drywall yourself, there is the investment of supplies like drywall screws, joint compound, and drywall mud to consider. If you choose to go the professional installation route, you can expect to pay a contractor about $30 to $70 per sheet.

Blueboard drywall panels are about $12 to $16 per panel. The installation of the blueboard panels themselves is also relatively straightforward and low-cost. The price contrast, however, is when you look at the cost of adding the plaster veneer. You'll likely have to hire a contractor and the installation process can cost about $5 to $10 per square foot (via Home Advisor). At this rate, you're looking at an additional $160 to $320 to veneer a standard 4 by 8-foot blueboard panel.