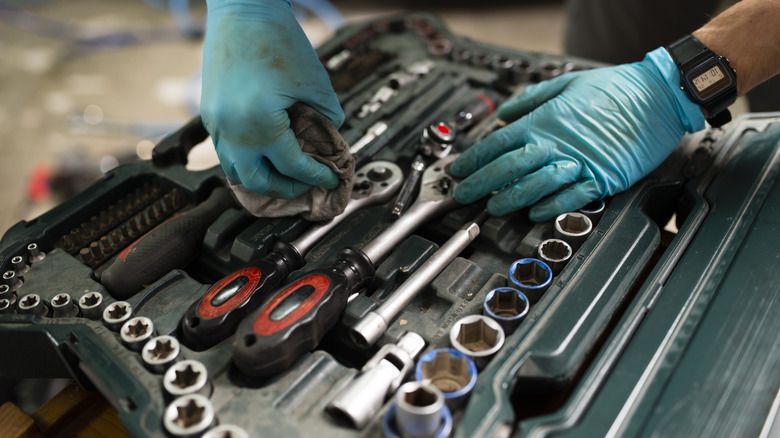

Here's How To Keep Your Tool Sockets In Their Best Shape For Years & Years

We may receive a commission on purchases made from links.

Sockets endure constant friction, grime, and exposure to the elements, but with proper care, they can last years without losing their grip. Keeping your tools clean, lubricated, and stored properly is the best way to ensure they are ready to work when you need them. Start by removing built-up grease and debris, something that can be easily done without harsh chemicals. A soak in warm, soapy water will loosen most dirt, especially when combined with a soft-bristle brush to scrub away any stubborn gunk hiding in the grooves. Vinegar is an incredibly versatile cleaning tool, and for more corroded sockets, a bath of one part vinegar to two parts water for thirty minutes will dissolve rust without damaging the actual metal.

Drying your sockets is just as important as cleaning them. Leftover moisture will accelerate rust, so use compressed air to blow out any water left in the crevices, followed by a microfiber towel to wipe the surfaces completely. Lubrication comes next, and just a light coating of machine oil or silicone spray will help protect against oxidation. Avoid heavy grease, which can attract dust. Finally, proper storage helps prevent damage. Keeping sockets clean and dry in an organized rack is much safer than having them rattle around loose in a toolbox, which causes nicks and scuffs to their otherwise smooth surfaces.

Tips for restoring even the grimiest sockets

For sockets caked with grease and rust, a deeper cleaning can help restore them to like-new status. Using ultrasonic cleaners, like this Creworks cleaning machine, is the most thorough way to ensure a proper cleaning. High-frequency sound waves dislodge debris in every crevice without the need for scrubbing. These machines are worth it for professionals and DIYers who want to keep their tools lasting as long as possible.

Make sure you pay close attention to the drive end of your sockets as well. Built-up grime where the socket connects can weaken the tool's grip and ruin the edges of both the socket and the ratchet. A small pick or brush can get into those tight corners and clear any compacted dirt. For chrome-plated sockets, avoid steel wool or wire brushes, which can scratch the finish. Storage upgrades can further extend socket life. Making your own DIY socket organizer or getting custom-cut foam inserts helps prevent sockets from shifting and smacking into each other. Adding a silica gel packet, like the ones found in shoes, can help absorb moisture in your toolbox, keeping the interior dryer for your metal tools.

Common mistakes that can ruin sockets

Even some well-meaning maintenance can backfire if it's done incorrectly. Storing sockets in a leather roll may seem tidy, but due to its porous nature it can trap humidity and promote rusting over time. Another overlooked error is mixing socket brands on the same rail. Slight variations in size can cause unnecessary friction when sliding them back and forth, wearing down the sockets and rail over time. This is one advantage to buying a brand-specific pre-loaded toolbox, as they often come with specific sections to keep your tools organized, and there's no worry of mixing tools.

You'll need to look out for environmental factors as well. Leaving sockets lying out in a garage or truck bed subjects them to temperature swings, especially in humid climates. Using your tools improperly could also ruin your sockets. Over-torquing a socket with impact tools can create tiny micro-fractures in the metal, leading to sudden failures. Keeping your sockets organized and in their proper place is an important step to increasing the lifespan of your tools, and saving you money in the long run.