15 Old School Tools That Went Obsolete

Most tools are here to stay. The hammer has been around as long as we have needed to apply force to other objects, and the crowbar has been with us as long as we've needed leverage to pry something up. And we'll probably always need these tools. But some tools change dramatically or even go out of style completely over short periods of time. For instance, you probably do laundry very differently from your great grandparents. Because of new inventions that make life simpler, we've left certain tools, like the washboard, in the past.

It's beneficial to take a look back at the old-school tools nobody uses anymore, because they can give us a better understanding of history. The tools we use to get our jobs done or even clean our houses have a great effect on our material circumstances. With greater efficiency at home, we have more time on the weekends. With greater efficiency at work, we produce more value. Or maybe you're just somewhat of a luddite and you're looking for some archaic tools to use in your own life.

Reel mowers are now mostly only used on putting greens

If you were a child of the mid-century, you probably remember push reel mowers. Maybe you feel faint nostalgia when reminded of this tool, but that feeling probably dissolves quickly when you remember how challenging it was to push one up a hill on a hot day. These mowers do not have a motor, but are powered manually, and their horizontal blades slice through the grass like scythes. Professional landscapers still often use reel mowers (usually more modern versions with motors though) on putting greens, because they offer the cleanest cuts.

Since reel mowers do not work well on uneven surfaces and struggle with overgrown grass, they have been all but fully phased out for personal use. The rotary mower, which spins horizontally and is propelled by a motor, became popular in the '60s and '70s, and is now standard among homeowners. If you want a closer cut, you can still use a reel blade, but we recommend you purchase one with a motor. Some horticulturalists even say that reel mowers are the best for a healthy lawn.

Bumper jacks can't be used on newer cars

Cars haven't always been built the same. For instance, if you own a vintage car that was built before the '70s, its bumper was probably made of steel, which allows you to lift the car from its bumper. That's why if you've ever had to change a tire in an older vehicle, you may have used a bumper jack. These pneumatic devices are no longer used for newer cars, because bumper designs have changed.

In the late '70s and early '80s, federal regulation changes led automotive manufacturers to begin using plastic bumpers. These bumpers are safer because they break on impact, rather than transferring the energy to the rest of the vehicle and its occupants. That's why if you try to use a bumper jack on a newer car, the bumper will break. Scissor jacks, trolley jacks, and bottle jacks have largely replaced bumper jacks for this reason. They lift the car by applying pressure to the car's frame, which is made of materials like steel and aluminum.

Braces and bits have long been replaced by electric drills

This is a tool that's almost never used anymore, although it was once a ubiquitous feature of every work bench or construction site. The only chance you have of coming across a brace and bit now is in an antique store or at an estate sale. The tool originated in Europe in the 1400s, and at the time, must have been a godsend to the carpenters and craftsmen. The mechanics are as simple as they are ingenious — a jaw holds the bit, the handle turns the bit, the ratchet allows the handle to turn the bit with a back-and-forth motion, and the head allows the user to apply pressure directing the bit into a piece of wood. This was the best way to drill a hole through a piece of wood, until the electric drill.

While two Australians invented the first electric drill in 1889, the portable drill did not come about until 1894. Black & Decker began popularizing the concept in 1917 when it started manufacturing a drill modeled after the Colt revolver. During the post-World War II period, the electric drills became more common for household use. Black & Decker also invented the first cordless drill in 1961, but they did not become widely available until 1978 when Makita released its own design. As these products have become more available, the once-screaming demand for braces and bits has diminished to a whisper.

Geared hand drills fell out in favor of electric ones

After braces and bits revolutionized carpentry during the Middle Ages, numerous variations were developed and eventually patented over the next several hundred years. The next major breakthrough occurred at the turn of the 19th century, when the first geared drills started to appear, but the original American patent for a geared drill was not issued until 1838. This technology soon became very sought after among carpenters and metal workers, because it allowed them to drill holes with greater ease. The 1870s saw an expansion in the manufacturing of geared drills, which was facilitated by the standardization of parts.

But the geared hand drill did not totally replace braces and bits. The two tools just filled different roles. Geared hand drills spun the bit much faster, which allowed the tool to drill small pilot holes for screws. Braces and bits, on the other hand, offered more torque to drill larger and deeper holes. Woodworkers also considered braces and bits to be more precise. The advent of electric drills replaced both mechanisms.

Yankee screwdrivers was an old school version of a ratcheting screwdriver

The spiral ratchet screwdriver, also known as the Yankee screwdriver, was patented in 1895, and it became popular among laborers and craftsmen for its ability to save both time and effort during projects. Using a ratchet mechanism, the tool allows you to push the handle to either drive or remove screws. By flipping a switch, you can control whether the tool loosens or tightens. The concept is that it is easier on your hand, especially during projects that require putting in or removing hundreds of screws, to push than to twist. If the bit wears out, you can simply replace it and keep the rest of the tool.

Almost no one uses this tool nowadays, and you're unlikely to run across one. They have been replaced by electric drills, which require even less physical effort. Otherwise, to tighten or loosen a single screw, you might as well just use a non-ratchet screwdriver. There is one scenario when you might need this type of screwdriver. If you're working around flammable chemicals, you should avoid using battery powered drills because they can produce a spark.

Pedal and crank grinding wheels were used to sharpen saws, knives, and more

Carpenters need saws, knives, and chisels, and they need to keep them sharp. Throughout the ages, carpenters have sharpened their tools against the abrasive surfaces of whetstones. Dating back tens of thousands of years, humans held stones in their hands and honed their blades against them. In the 1800s, foot-pedal and hand-crank lathes first appeared, although Leonardo Da Vinci drew designs of treadle-powered grinders hundreds of years before. The foot-pedal grindstone is useful because it frees the hands to hold the blade firm. We have moved away from crank-operated grinding wheels with the advent of electric motors.

Lathes are almost exclusively powered by electricity today. This allows you to flip a switch and sharpen a blade with very little effort. Starting in the late 1800s, electric motors were used to power grinders in industrial settings. Throughout the 20th century, electric grinders became popular for personal use. This change was facilitated by expanding access to electricity for the average consumer. That's why you'd struggle to find anyone who still used a crank-operated grinding wheel outside an antique store.

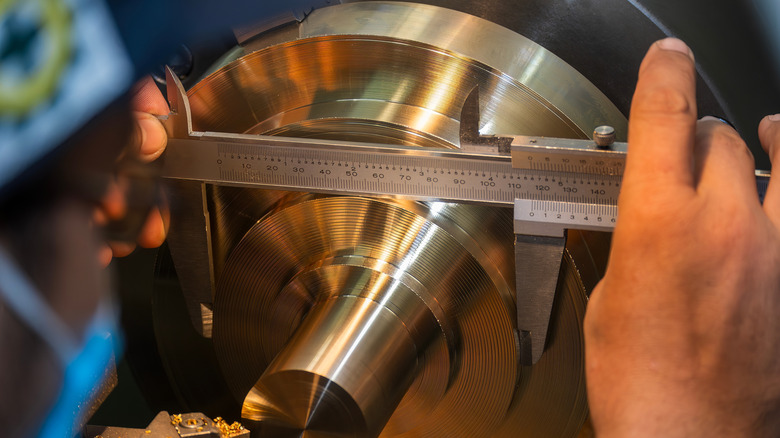

Dial vernier calipers have since gone digital

The dial vernier caliper is used to make precise measurements. They are necessary in fields like manufacturing, medicine, and engineering. The tool is particularly useful for measuring the diameter of curved objects, like bolts or pipes. A French mathematician named Pierre Vernier invented the tool in 1631. The tool is made up of a main scale, a ruler, which is attached to a slide that allows for very specific measurements to be made with certainty. The slide and the ruler also have parallel arms that will straddle curved objects to their greatest width to measure a diameter.

Vernier calipers are still used today, but they have been replaced in many instances by digital calipers, which look exactly the same, except they have a digital monitor. Digital calipers instantly show the reading, they allow you to switch between metric and imperial, and have higher accuracy. But, unlike regular calipers, there is a risk of the battery dying.

Washboards were how people cleaned clothes before washing machines

The evolution of tools has made daily life simpler. There was a time, not long ago, when people had to hand scrub each individual article of clothing. This process took hours or even entire days. At the time, people would complete their laundry by filling a bucket with suds and scrubbing clothing against a washboard. If you're not familiar, a washboard is a tray with either wood or metal ridge. Most people's frame of reference for this technology nowadays is something they saw in an old movie or a period piece. In the United States, you're more likely to see someone using a washboard as a musical instrument than for its designed purpose.

While people still use washboards in many parts of the world, the electric washing machine almost completely replaced it in the United States during the 20th century. Washing machines save time not only because they can wash an entire load at once, but you don't have to actively participate with the washing process like you would with a washboard. The Hurley Machine Company introduced the United States to its first electric washing machine, the Thor, around the turn of the century. If you do feel inclined to try using a washboard, you will save water and do the environment a favor.

Ice picks lost relevance once modern refrigeration came around

Most people know this tool from mob movies or detective novels, where they are used for nefarious purposes. Its designed purpose, however, is to break chunks off a block of ice. The tool has a metal spike with a wooden, plastic, or rubber handle. From the late-19th through the early-20th century, ice was shipped hundreds of miles via rail after blocks were harvested from cold environments. Workers would break up the blocks using axes and picks. The blocks would eventually end up in people's ice boxes to keep food cold. When folks needed a few cubes, they'd pull out ice picks.

The advent of refrigeration technology in the early 20th century replaced the need for ice picks, which were no longer convenient for daily use. Most Americans had refrigeration by the mid-'40s. Nowadays, people use ice trays, or their freezer has its own ice machine.

Wheel hoes can still be used today, though engine-powered ones are more convenient

For thousands of years, farmers relied on horses and oxen to pull plows, but to turn the soil in small fields or gardens, most people had to use hand tools like picks and hoes. This changed at the turn of the 18th century when an English agriculturalist named Jethro Tull invented the wheel hoe. The simple tool has two wooden handles, a plow, and a wheel. This allows the user to push the plow into the earth with a little bit of force, while the wheel will facilitate forward motion.

Gas-powered cultivators have largely replaced this technology. The cultivator has two handles, two wheels, an engine, and several rotating blades. But if you don't want to spend hundreds of dollars, you can still use a wheel hoe. One valuable aspect of this robust tool is that it does not require the same expensive and complicated repairs as a combustion engine. If you have a smaller garden, you can also just combat weeds with a regular hoe.

Plumb bobs were the original levels

Straight lines are essential to carpentry. When a line is parallel to the flat ground, it is flush, but when a line is perpendicular to the earth, it is plumb. To make sure a beam is plumb in relation to the floor and ceiling, you can use gravity. All you need to do is attach a weight to a string and hang the string from the ceiling. This trick has been used for thousands of years in surveying, art, and construction. Ancient Egyptian artwork even depicts craftsmen using plumb bobs. One of the convenient aspects of plumb bobs is that you can make them with fishing weights or keys.

Plumb bobs are still useful, but new technology has largely phased them out. Laser levels are just as precise as plumb bobs, and you don't need to bring them. You can also use a spirit level, which works using air bubbles in an alcohol solution. If you keep a spirit level in your tool kit, you can pull it out whenever you need to check if something is level.

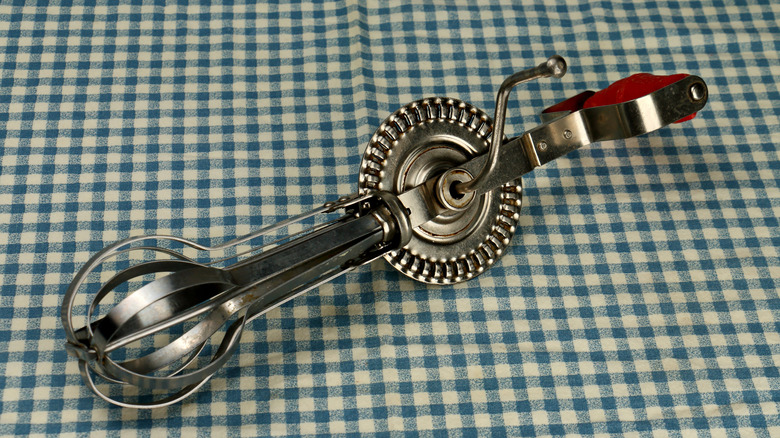

Hand-crank mixers went electric

Whisks have several uses in the kitchen. They blend ingredients, whip egg whites into peaks, and turn heavy cream into whipped cream. Some people use forks as substitutes, but the looped wires make whisks a perfect mixing tool. The action of whisking can wear out your hand, especially for those who have to whisk for a living, which is why the first hand-crank egg beaters were invented during the 19th century. The mechanism works similarly to geared hand drills. Instead of stirring rapidly, which is especially hard on people with arthritis, all you have to do is turn a wheel.

Since the invention of electric hand mixers, very few people use hand-crank mixers anymore. Instead of turning a lever, you only have to plug the machine into the wall and push a button. The motor in your electric mixer will turn the whisks faster than a hand-crank mechanism ever could.

Drawknives have been replaced by electrical alternatives

The drawknife is a fixed blade with a handle on either end. The user pulls the blade toward their chest to quickly remove chunks of wood and round out surfaces. The tool also works well for removing bark. Unlike crude tools, such as axes, the user has moderate control of how much wood a drawknife removes. However, drawknives do not give the user as much control as more precise tools like chisels or carving knives. These ancient tools are less common today because of the advent of must-buy power tools, which make woodworking more efficient than it ever has been.

Since drawknives have a broad range of applications, there are lots of electrical alternatives. Some carpenters use bandsaws to cut away large pieces of wood. This is essentially a table with a fixed blade that you push your piece of wood into. You can also purchase a debarking attachment for your chainsaw. While the practical advantages of drawknives have diminished over the past century, craftsmen will always use drawknives for the sake of tradition and affordability.

Shoe arcing machines aren't needed for modern cars, as the use of them led to released asbestos

Most people, unless they've worked as a mechanic, are probably unfamiliar with shoe arcing machines, but these clunky machines used to be fundamental to automotive maintenance. This machine's job was to grind brake shoe linings to match the vehicle's brake drum. The process of grinding brake shoes only takes a few minutes, and the machine can be set to extremely specific measurements. Once you've grinded the brake shoes, your vehicle can slow down with greater ease and efficiency.But this technology is no longer used for the vast majority of cars.

This tech was found to release harmful asbestos from brake linings, so it is only ever used anymore when it's necessary to fit new brake linings to vintage cars. Newer vehicles utilize disc breaks, which do not require special fitting. When disc brakes wear out, mechanics tend to just replace them, so they never have to be grinded back into shape.

Air ratchets have largely been replaced by cordless impact wrenches

You can hook a hose to an air compressor and use the air to power a ratchet tool, which can remove heavy bolts. This pneumatic tool has long been standard in garages. But air ratchets are going out of style quickly, as cordless impact wrenches replace them, at least for home use. At the end of the day, the issue comes down to affordability, space, and convenience. For instance, if you own a cordless impact wrench, you don't have to purchase and store an air compressor.

With a cordless impact wrench, you don't have to worry about the hose getting in the way or limiting where you can take the device. You just have to make sure to keep the lithium batteries charged. This tool is not only quieter than cordless impact wrenches, but they also offer similar levels of torque. In auto shops, air ratchets are still used commonly because they are tough and easy to fix.