We Compared WD-40 Against PB Blaster For Stubborn Bolts & A Dark Horse Emerged

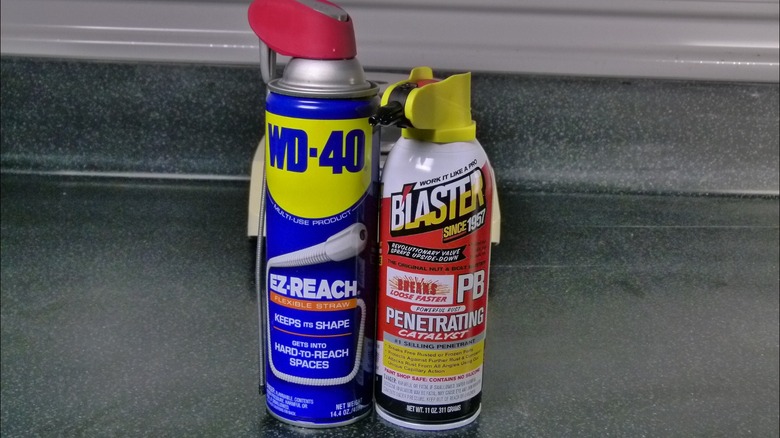

There's a small but active (and vocal) online community of machinists, mechanics, and gearheads who are mildly obsessed with a single, simple question: What is the most effective penetrating oil? It's not a trivial thing if you've spent half an hour cutting bolts to free an ATV exhaust pipe or, worse, you've snapped off a stud to which a lug nut has firmly rusted. Penetrating oils are designed to, among other things, free up components frozen together by the chemical/mechanical magic of corrosion. Everyone seems to have their favorite, including some homemade versions, but the most popular by a mile are WD-40 and what we're calling PB Blaster.

Despite packaging that looks as if it were designed by someone unsure of its purpose and overly fond of free fonts, PB Blaster enjoys a devoted fan base and a lot of popularity. WD-40 Multi-Use Product, on the other hand, clings to its brand so hard it can be difficult to tell when you've accidentally picked up another of the company's offerings. PB Blaster is mostly known for busting rust, while WD-40 is known for everything from reviving rusty patio furniture to warding off wasps.

What we wanted to know about WD-40 and PB Blaster

What really matters, though, is how WD-40 and PB Blaster perform in tasks they both claim to excel at. For those obsessed machinists, the primary question seems to be "How well do these products loosen rusty lug nuts?" Related questions include "How well do the products dissolve/remove rust?" and "How well do they prevent rust from recurring?" There have been two prominent and many obscure attempts to investigate the matter since 2007, when "Machinist's Workshop" did a fairly rigorous experiment that found both were better than nothing but not better than anything else.

We attempted to test three things: How much would each reduce the torque needed to remove rusty lug nuts (in our case, from a decrepit 1970s Craftsman lawn tractor)? How well would each remove rust from bolts submerged in them? And how quickly would each penetrate a test rig with a fairly tight seal? The lug nut test was risky because we had no way of knowing just how rusted-on the nuts actually were. It would have been a good idea to set a baseline torque that ensures the nut is actually rusted on, as YouTube auto mechanic CarsNToys suggests during his own tests (he went with a baseline of 25 foot-pounds). Because the torque can be so high with lug nuts on a vehicle, that doesn't really work since testing the torque might loosen the nuts.

Our plan to answer the great penetrating mystery

Here's a tip for anyone hoping to do experiments on a rusty old lawn tractor: You'll need to move it into your shop, and if it won't start you'll need to push it, and if its tires are flat you'll need to inflate them, and if they won't hold air you'll need something like another riding mower to pull it, and if that mower's battery was taken out to power Christmas toys ... well, you get the idea. We eventually got the thing near the workshop, where we dropped 10 milliliters of each penetrating oil onto its own set of lug nuts and waited two hours. We planned to use a certified-accurate torque wrench to repeatedly attempt to remove the nuts, incrementing the wrench's torque a little each time.

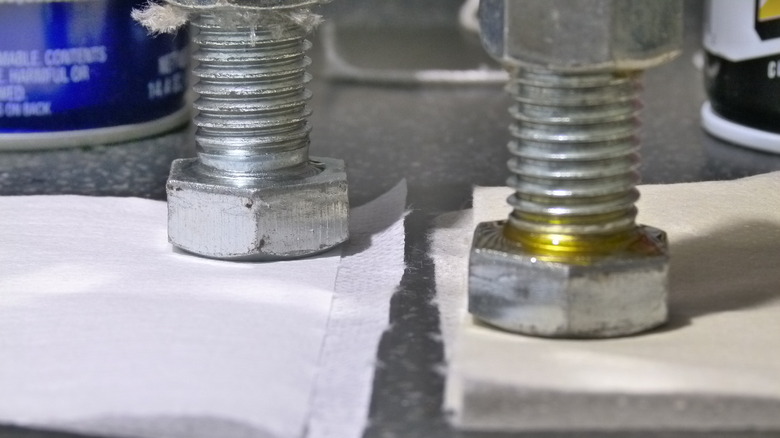

The rusty bolt test was far simpler. For this one, we dispensed a few ounces of each penetrant into a small container, into which we submerged a couple of similarly rusty bolts for 12 hours, agitating them occasionally, and then compared the condition of each. Note that, for both of these products, the package directions indicate far shorter wait times ("around ten minutes" for WD-40, "a few minutes" for PB Blaster). Finally, we tested (twice) the penetration speed by driving bolts into long coupling nuts packed with a 1.5-millimeter silica wick. The idea here would have been to use rusty bolts and coupling nuts, but we didn't have two similar sets of them.

Trusting the wisdom of others

In spite of online arguments, most previous tests (including the "Machinist's Workshop" experiment and another prominent set of tests done by YouTuber @projectfarm) found that the products perform very similarly when it comes to un-seizing bolts. We hoped to find something more conclusive but ultimately didn't. Both had very similar torque averages and were very low: 27 foot-pounds for WD-40 and 24 for PB Blaster ... low enough that it's possible they weren't seized to begin with. The rusty bolts looked very similar after being treated ... and quite rusty still. When both products penetrated our silica test rig within a few minutes of each other, we repeated the test and found one possible difference in that PB Blaster eventually penetrated the silica wick on the second try (sometime between 4 and 6 hours), while the slightly more viscous WD-40 did not.

This brings us to our recommendations, informed by the recommendations of all the testers before us. In the experiments we found online, Liquid Wrench outperformed both WD-40 and PB Blaster and was, in turn, outperformed by a homemade concoction of automatic transmission fluid and acetone. Based on all of that and our own inconclusive attempts, our findings were underwhelming, and our recommendations are nowhere near scientific. If we were stocking the chemical cabinet of a workshop with limited funds, we'd go with WD-40 for its myriad uses and solid reputation, and Liquid Wrench for getting rusty things unstuck without toying around with acetone.