Why You Shouldn't Skimp Out On Your Electrical Boxes, And The Few Exceptions To The Rule

We may receive a commission on purchases made from links.

You should always buy the best electrical boxes for your DIY wiring projects. Metal models are generally more expensive than plastic, and if you ask four electricians whether the former are better than the latter, five will say yes. It's such an article of faith among the Klein toolkit that no one ever stops to ask, "Well, what do you mean when you say 'better'?" And in a way, that's as it should be. In terms of the quality of the actual device, metal boxes are better, full stop. But there are other aspects that might reasonably be folded into quality, like cost and ease of use, where plastic soundly kicks metal's butt splice.

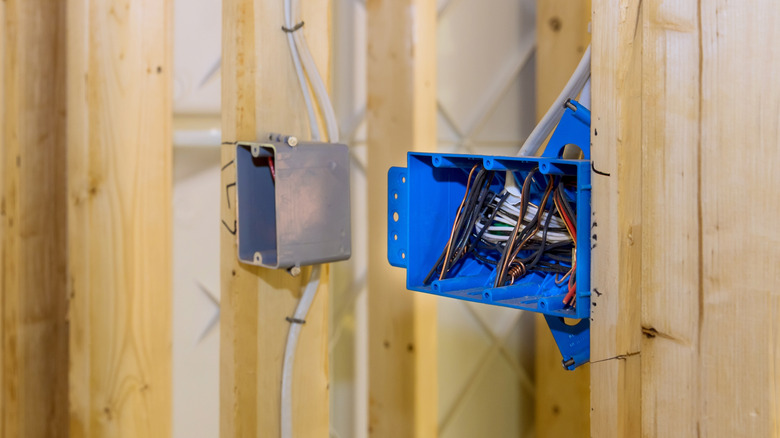

So let's come at this carefully, starting with what we're talking about. That is, wall boxes for residential wiring, particularly the most common of the many types of junction boxes in your home. More specifically, single- and double-gang boxes for switches and receptacles and the 4-inch round boxes commonly used for things like ceiling luminaires, wall sconces, and smoke alarms. We'll toss into the bargain all derivatives of these, such as shallow "pancake" boxes, junction boxes, new and old work (remodeling) boxes, and outdoor boxes. For the moment, we'll leave boxes for mounting ceiling fans out of the equation. What we will see, in short order, is that the very best and the very worst wall boxes are plastic, all things considered — except when you must use a metal box.

When are metal boxes better?

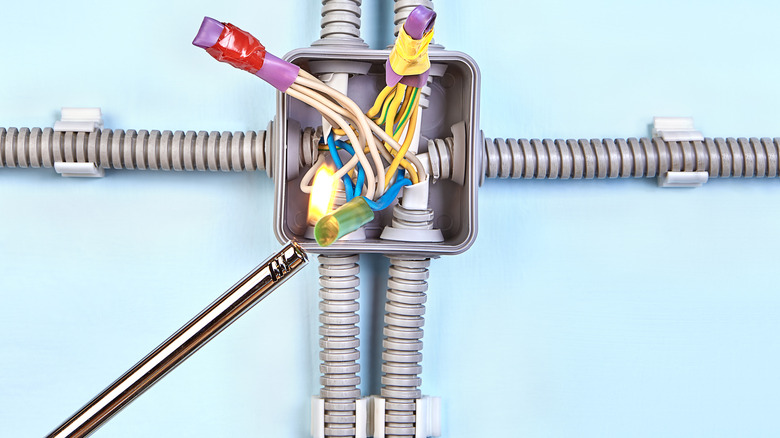

The briefest conversations in the internet electrician-osphere (or with the caged parrots commonly known as search engine AI) will teach you that metal boxes are better because they're stronger and won't melt or burn. That is, for the most part, nonsense — toughness doesn't always matter. For exposed areas like unfinished basements and the uncommon case of exposed, surface-mounted wiring and handy boxes, you might occasionally take a box's toughness into account. But you mostly need metal wall boxes because they're metal. If metallic conduit or metal-sheathed BX cable terminates at a box, that container should also be metal so it can be bonded for continuity of grounding. In that case, there's no choice in the matter. It also used to be true that ceiling fans and heavy fixtures required metal wall boxes, but fan-rated plastic boxes are fairly common today.

Even the "exposed box in an unfinished basement" case is a bit suspect. Here it's useful to understand electrical code mumbo jumbo a bit. Like pretty much all wiring and boxes, the exposed wiring and boxes in (for example) an unfinished basement must be protected from mechanical damage. You can accomplish this using metallic or nonmetallic conduit, but if not, you must use one of the various means of protection described in National Electric Code 300.4, which includes things like notches or bored holes in wall studs. If this seems vague, that's because it is. But what is certain is that you can use either metallic or nonmetallic conduit and its accessory boxes to protect wiring and devices ... meaning that metal is not required.

The problem with metal box orthodoxy

Purist metal box orthodoxy often fails to take into account practicalities like expenses or the requirements of law or building codes. Author and remodeling contractor Herrick Kimball's YouTube video declaring that steel boxes are better is a great example of this phenomenon. While Kimball is 100% factually correct and seems perfectly reasonable and earnest, one wonders if this video is a very subtle satire of some kind. He repeatedly points out a narrow benefit of metal boxes, then undermines his own point by illustrating how much more difficult they are to work with. Even his base comparison between a 4-inch metal box and a 2-by-3.5-inch plastic box is an apples-to-cantaloupes affair — there are smaller metal boxes and larger plastic boxes available for comparison.

All of Kimball's explanations illustrate the faulty single-mindedness of metal-box orthodoxy. He opines that the device-mounting threads can be more easily stripped in plastic boxes, noting that this is easily fixed with a drywall screw for plastic boxes, compared to tapping the hole for a new screw size when a metal box is stripped. Kimball also says that unlike new work plastic boxes, metal boxes can be positioned anywhere between studs ... by cutting a 1-by-4-inch board to fit between them, adding four pocket holes with a Kreg jig, positioning the board using a homemade jig, setting the height off the floor with yet another jig, screwing the board to the studs with four screws, and then securing the box to the board with three sheet metal screws. It's like saying one particular car is better because you can build a garage around it anywhere you go.

Your plastic box won't distort, crack, or melt

Generally speaking, the notion that plastic electrical boxes aren't up to the job is belied by the facts — and by the National Electrical Code. There are many materials described as "plastic" and many grades of electrical box that use each of those materials. Some are all but indestructible, but that isn't even the point. The point is that a box secured behind residential drywall is unlikely to experience any of the extreme mechanical stresses that metal box fans like to mention. And if such a thing were likely, electrical code already requires that boxes and wiring be protected, specifically mentioning plastic assemblies as a way of accomplishing that. So what exactly are the environmental conditions that make metal boxes safer? One frequently cited example of harsh conditions is a damp or wet environment that can lead to corrosion, but metal boxes are far more susceptible to corrosion by water.

Fire is a slightly different issue, and metal boxes are undoubtedly more fire-resistant than plastics. But how significant is this benefit? Herrick Kimball illustrates the fact that metal boxes have a higher fire rating than PVC by melting a plastic box with a propane torch. This is unsurprising, since an average propane torch burns almost twice as hot as the average house fire. It's also worth noting that one of the cheapest plastic boxes available ($1.11 at Home Depot) has a two-hour fire rating, as do most models we looked at. And consider that electrical boxes should match the fire rating of the wall they're in, and a two-hour fire-rated wall is considered a fire wall.

The benefits of plastic electric boxes

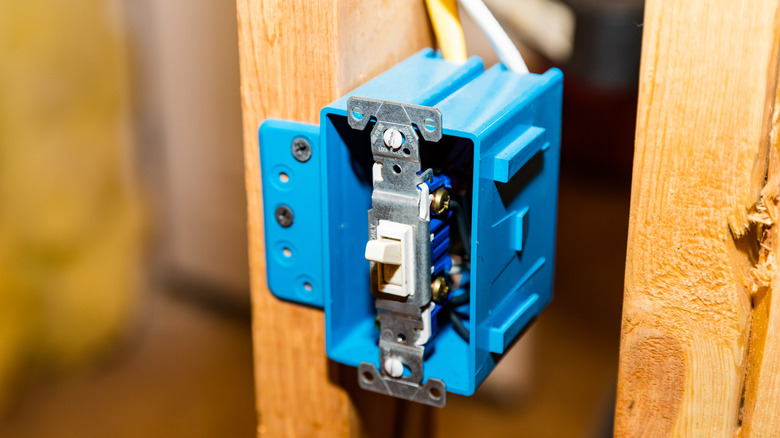

Plastic electrical boxes needn't be on a defensive footing all the time since they have benefits of their own. They are generally cheaper than steel, and they also don't require the various connective doodads that metal boxes need, such as plaster rings, cable clamps, protective bushings, and ground screws. All of those things not only cost money but also complicate installation, which brings us to our next point — setting up a plastic box is almost always easier than a metal box.

Niceties like captive nails for attaching plastic boxes make wiring easier in general, as do other features like depth guides and integral cable clamps that make it far easier to secure cable in plastic than in metal models. They're also non-conductive, which has safety benefits and means you don't have to bond them to a grounding conductor if you're using nonmetallic (NM) cable — that is, Romex, which is not self-grounding. Another benefit is that plastic boxes are less likely to be corroded by any sort of moisture intrusion.

But one of the biggest benefits of plastic electrical boxes is the sheer variety of boxes available. The scope of what is available is remarkable — nail-on boxes, flanged boxes, old work levered boxes, adjustable boxes, boxes with snap-on low-voltage rings, boxes with metal spring ears and extension rings, fan-rated boxes, shallow boxes, floor boxes, fire-rated boxes, outdoor boxes, square/round/octagonal boxes, and many more. While most of these are also available in metal, they're also less common in your average big-box home center ... probably because the plastic versions work just fine in most circumstances.

Not all plastic boxes are created equal

So plastic boxes are cheaper, easier, sufficiently durable, and safe. But after this love letter to plastic electrical wall boxes, it must be noted that not all of them are created equal, and not all plastics are equally lovable. Some, like polycarbonate, can be so impervious to dents, deformations, impacts, and corrosion as to be superior to metal alternatives. These are rated for high impact and particulate resistance, and they can be weatherproof even to the point of prolonged submersion. Other plastics have their charms, as well. Fiberglass-reinforced polyester boxes resist shattering even in low temperatures and exhibit no distortion in high temperatures. Some thermoplastic PVC boxes are incredibly strong and won't break, flex, or deform under the worst of circumstances.

Other plastic boxes involve trade-offs. ABS boxes are affordable, impact-resistant, and durable, but they can suffer when exposed to high temperatures or certain chemicals. Phenolic resin boxes can be brittle, and polyamide plastics degrade with UV exposure and can be quite weak when used to make thinner-walled boxes (though they are extremely impact- and chemical-resistant).

Indeed, thin-walled boxes of most materials can be troublesome. But the real issue with cheaply made plastic models arises when they aren't rigid enough and get deformed when installers don't perfectly cut out electric boxes in drywall. They might also move a lot after installation, which can lead to failed electrical terminations. And beware the integral cable clamps on cheaper boxes, which might be poor or nonexistent. Ultimately, you often get what you pay for, and skimping by buying a low-quality plastic box is a decision you'll live with for a long time.