The Wood Cutting Hack That Will Save You Time And Effort

We may receive a commission on purchases made from links.

Measuring boards for a bunch of identical cuts is a notoriously difficult thing to do consistently. Pro carpenters are very good at both measuring and cutting precisely. So precisely, in fact, that they have terminology ("leave the line," "take the line," and even "split the line") for whether to cut on or just next to a pencil mark. But because measuring with almost comically difficult-to-use instruments and ripping through wood with a spinning blade are both very coarse analog processes, real precision can be very hard to achieve. It's good, of course, to have quick and accurate wood-measuring hacks in your back pocket, but measurement will always introduce errors into your work.

Enter the stop block and its many cousins in the carpentry and woodworking crafts. Most stationary power saws have a form (or 10) of the stop block — a simple device that's fixed in place to hold a workpiece at a specific distance from a saw blade. The stop block defines one end of the board, and the saw blade creates the other. It's an amazingly quick way to make many dozens of identical cuts. It's also a valuable method even if you only have to make a couple of cuts when you want to ensure that the boards are identical in length. This is one of those simple saw hacks that ensures a perfect cut every time, and they're used with miter saws, table saws, router tables, drill presses, and even with non-cutting operations like gluing boards together. Stop blocks are the simplest of jigs, and possibly the most valuable.

Simple DIY stop blocks for every saw

Instagram home design influencer Haylee Griffin (@homewithhay) uses a simple and effective stop block on her miter saw by spring-clamping a block of wood to the model's fence extension. For each identical cut, she simply slides the workpiece up against the stop, makes her slice, and moves on to the next. This is the principle behind most stop blocks — they attach to a saw's fence perpendicular to the blade to define a board's new length. A block attached to a table saw sled would serve the same purpose.

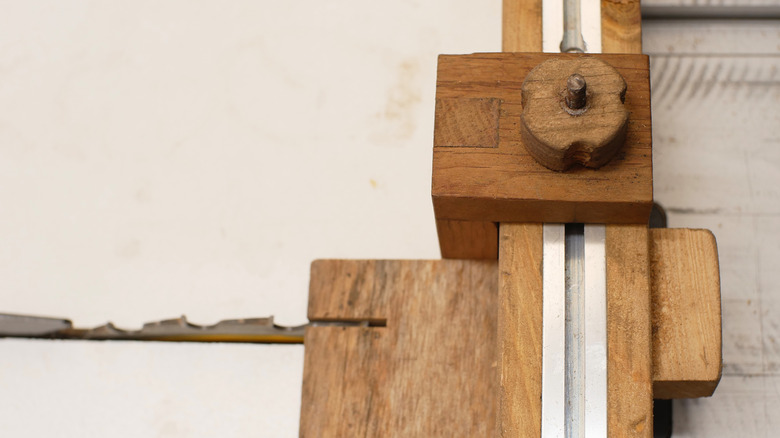

If you prefer, you can use something less prone to slipping than spring clamps (a C-clamp, for example). More elaborate DIY and store-bought stop block systems often lock within T-tracks, allowing you to position the stop along a track and then firmly screw it down. Indeed, many DIY stop blocks and jigs that incorporate stop blocks are more elaborate than simple blocks of wood. They might flip into place on a hinge or include a micro-adjustment mechanism or any of a number of other features.

Of course, a stop block doesn't have to be used for a full cut across a board. You can use it as a locator for a notch, as in the indexing spacer keys for finger joint jigs. Or you can attach a block to a router table fence to define the endpoints of a groove or slot that doesn't run all the way to a board's edge. (This also works with a hand-held router — simply attach the stop block or blocks to your edge guide to tell the router where to stop.)

Off-the-shelf stop block options

While woodworkers are likely to make elaborate stop block systems on tracks customized to their own workflows, they're also likely to buy commercially available stop blocks as part of the never-ending search for a better mousetrap. But DIYers and carpenters are often satisfied with the simple clamped block approach — or a store-bought solution that's easy and reliable. And there are many easy, reliable stop blocks on the market.

The most highly rated stop blocks on Amazon are, notably, also the simplest. The Powertec Universal Long Stop Blocks ($13.98 for two) are simple L-shaped pieces of anodized aluminum. However, these (and most top-ranked) stop blocks require that your saw fence has a T-track installed. If you're using your saw's factory-installed fence, that might not be an option for you. Many other T-track stop blocks offer a flip-down feature, useful if you want to save the saw's setup for a certain cut but need to use it for other cuts in between. A good option that doesn't require T-tracks are Rockler's Universal Fence Clamps, which will clamp to most fences directly. The Rockler clamps use any block of wood into which you've drilled a ⅜-inch hole as a stop block.

There is a whole universe of stop block possibilities out there, though. If you're using a nearby workbench to support the piece you're cutting — common when cutting long boards on a miter saw, for example — you might be better served by bench dogs rather than clamp-on stop blocks. Bench dogs fit into pre-drilled holes in the deck of store-bought or DIY folding workbenches and can serve the same function as stop blocks.