Troubleshooting Why Your Washing Machine Is Making So Many Sounds

Washing machines tend to be noisy, even when they are working correctly. But when you hear your washer run every week, it's easy to notice when something is wrong. Sometimes strange noises are caused by mechanical dysfunctions, which can take anywhere between a few minutes and the whole day to fix. These issues can be hard to diagnose because washing machines have dozens of parts that all interact with one another. You may not notice that one part has broken until it's affected other parts in the machine. It's also common for noise to come from something stuck inside the machine that probably shouldn't have been there in the first place. Issues with the drainage system can be a source of noise as well.

All machines have limited lifespans, but generally you should expect a washer to last for 10 to 15 years. Your machine will probably need repairs during that period of time, so do your best to prolong the life of your washer, and don't let strange sounds linger. This piece contains advice on how to diagnose and even repair mechanical issues indicated by noises. Even if you wouldn't choose to repair your washer on your own, it's good to understand the repair process so you can avoid getting ripped off by a technician. For extensive repairs, it's always best to go to a certified appliance technician because otherwise you might void your warranty.

Worn-out drive belts will make a squealing sound

While some newer washing machines don't have belts, most do. If your washing machine's drive belt is experiencing some wear, you might hear a squealing or screeching accompanied by a burning rubber smell during any of the machine's cycles. The drive belt is a circular rubber strap that connects to the motor and the tub or agitator, which is the spindle-shaped screw that rotates in the middle of top-loading washing machines (but not front-loading machines) to beat the clothes. The first sign that something is wrong with the drive belt is usually that the tub will stop spinning properly. This will leave clothes unwashed but soaking wet, because the drive belt also helps the tub to drain.

Over time, your drive belt can fray and even slip off its motor pulley or drum pulley. If the drive belt has broken completely or slipped off its pulleys, you'll hear a bumping and grinding and the tub will no longer spin.You'll have to look into the machine's internal components to replace the belt, so you need to unplug the power cord and possibly even shut off the water supply to the appliance. If you are having a professional repair technician service your unit, they will unscrew the front or back panel, then slip the belt off its pulleys and put a new belt snugly in place.

Faulty tub bearings will squeak and grind

Bearings allow your washer tub to spin smoothly. These steel balls often squeak when the seal that holds their lubricant breaks. You may also hear a grinding or even a roaring when it's time to replace your bearings. These sounds mean that the bearings have become an impediment on the machine's function. Tub bearings can be found where the shaft connects to the inner and outer tubs. In front-loading washer machines, these bearings are at the back of the machine, and in top-loading machines, these bearings can be found at the bottom of the machine.

Bearing failure is often linked to a worn or damaged tub seal, which allows soapy water to leak onto the transmission and shaft. First, this leakage will ruin the lubrication and then it will cause the bearings to rust and corrode. Using a washer with bad bearings will damage the other parts of the machine, including the transmission (especially in top-load washers).To replace the bearings, a technician will unplug the washer and remove its back panel. Your manual should specify if it's necessary to remove the washer's wash basket, inner tub, and transmission. If there is rust or cracks on the bearings, it's time to replace them. This process requires a technician to fully disassemble and rebuild the machine.

A worn motor coupling can make a clunking sound

If your top-load washer's tub won't spin, the source of the issue isn't always rooted in the drive belt or bearings. You can find the motor coupling between the transmission and the motor. The job of the coupling is to take power from the motor and send it to the transmission. You can tell the motor coupling is worn out when the machine fills and drains, but the washer tub won't spin. As the motor coupling starts to wear out, you may hear a clunking noise during the spin cycle. This will make it nearly impossible for the machine to clean your clothes, because you need movement and agitation to get dirt and stains out of fabric.

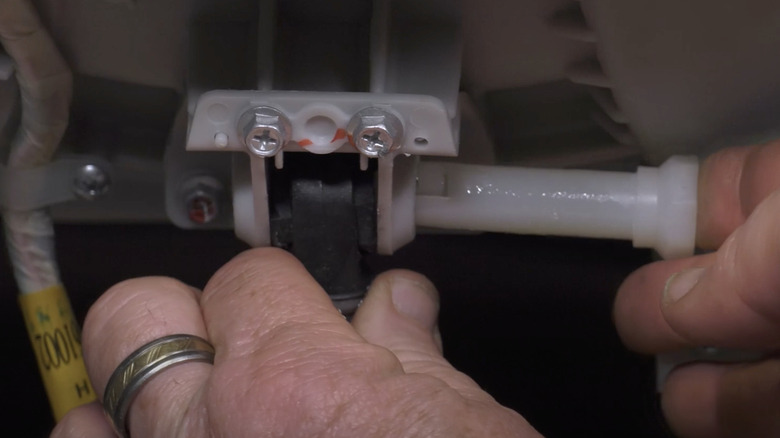

To find the coupling, you or your technician will locate the motor — it's usually mounted beneath the tub, near the transmission. The motor is a compact, metal or plastic unit, roughly fist-sized, with a pulley or shaft extending from it. The motor coupling connects this shaft directly to the transmission input. It will have two plastic triangular parts, known as forks, with one attached to the drive shaft and the other attached to the transmission shaft. There is a round rubber piece between the two forks that absorbs the torque. Depending on your machine's design, your tech may need to remove the drain pump or motor. They should look for cracks or other forms of serious wear, and if you find them, it's time to replace the coupling. The technician will use a screwdriver or pry bar to detach the old coupling pieces and then press the new three-piece coupling parts into place.

Misaligned feet will make a thumping sound

One of the first things you should check when your washing machine shakes too much is the feet. Misaligned washer feet will cause a thumping sound, particularly during the spin cycle, because the machine will bounce back and forth. You may think that the root of the problem is something internal, and it may be, but you'll definitely want to rule out uneven feet before you poke around inside the machine. The process of adjusting the feet is not intuitive and can be somewhat of a challenge, especially considering how much weight is on them.

First, place a level on top of the machine to determine which side or corner is too low. Then, shine a light under the machine and rock it to determine which foot is uneven, and use a wrench to loosen its lock nut. Each leg has a lock nut to prevent it from raising or lowering. You can turn the legs clockwise to lower them and counter-clockwise to raise them. After you adjust the feet, check the level again, and then tighten the lock nuts to prevent the feet from moving. You can also put anti-vibration pads under the feet to stabilize the machine on uneven floors.

Unbalanced drums make a banging sound

The drum is the part of your washing machine that holds the clothing, and when it spins unevenly, it makes banging or thumping sounds. These are especially pronounced because you are hearing a metal basin slap against the internal components of you washed. Sometimes this issue is caused by the clothes being packed into the washer unevenly. You should check that first, because you don't want to take your washer apart if there isn't actually a mechanical issue. Rearrange your clothes, make sure heavy items like jeans or towels are evenly distributed, and then run the machine.

Your machine might also be unbalanced because someone forgot to remove the shipping bolts, which keep the drum from rattling around during delivery. The first thing you should do, if you can, is call the delivery or installation company to get the issue remedied. The four bolts should be on the rear of the washer and they can be removed using a crescent or socket wrench. If this is not possible, you're may need to call a technician to diagnose and repair a worn-out snubber ring, which is a felt material that prevents the drum from hitting the inside of the machine's metal shell.

Blocked drain pump filters cause a humming noise

Drain pump filters help prevent your washing machine's pump and drain system from getting clogged by lint, hair, and bits of paper. This also protects your clothes from becoming resoiled. A front-load washing machine's filter is typically located at the front bottom corner, where you'll see a small compartment covered by a lid. When your washing machine fails to drain, it's likely because the filter is clogged with debris. When your filter is obstructed, you'll hear a humming noise as the pump struggles to push water through. A clog could cause the self-locking mechanism not to disengage after the wash cycle has concluded. The last sign is also just a general decline in performance, which might mean that the clothes are still soggy or even covered in soap after the cycle completes.

You can clean your filter in less than an hour. The first step is to unplug the washer and consult your manual to find the filter.For top-load machines, the filter is usually behind the back panel. Once you locate the filter, you might find an emergency drain hose next to it. Remove the stopper from this hose and drain it into a bucket, and then reinsert the stopper. Next, unscrew the filter, and scrape any gunk into the trash. Then take the filter over to the sink, run hot water over it, and use a toothbrush to scrub it clean.

Bad clutches will sometimes squeal

The washing machine's clutch connects the transmission to the inner tub, allowing the drum to reach full spin speed gradually. It helps the motor control how quickly the washer accelerates into the spin cycle, preventing strain on the drive system. If you're not a mechanic, this mechanical terminology can be confusing, but the essential role of the clutch is to control the washer's cycling between agitation and spin. Agitation is a back-and-forth motion that scrubs clothes, and spin is a quick rotation that extracts water from the clothes. The clutch looks like a small hubcap with a hole in the middle that allows it to attach to the transmission. Inside, there are various springs and friction pads that regulate the drum's rotation. A bad clutch usually causes a squealing sound or even a burnt smell as it struggles to spin the drum. This replacement process is not easy and requires a technician to disassemble the machine.

The technician will remove the back of the machine to access the clutch, which could be located between the outer tub and the transmission or between the transmission and drive pulley. They will check for signs of burning or wear, then detach the ring clip in the center of the drive with a screwdriver and replace the clutch, as well as its spring and clips.

An overloaded washer can lead to a thumping sound

One of the best ways to protect the motor coupling, bearings, and seals of your washing machine is to load it correctly. We've all rushed through our laundry as fast as possible, but it isn't worth the money and time spent repairing or replacing the machine. If you overload your washer, you may not notice problems immediately, but over time, the mechanical components will wear down. You may hear a thumping or grinding, especially during the spin cycle, or even a squealing as the belt struggles to turn the overloaded drum.

One of the ways that overloading a washer can damage it is by pushing orphan socks and underwear down the drainage line.A good rule of thumb is to never load the machine more than three-quarters full.Clothes need to agitate and tumble, so overloading will also prevent them from washing correctly.

Foreign objects will clatter

While you're doing your laundry, you need to empty the pockets of your clothes. Foreign objects like coins, hair clips, and keys often just clatter around and don't cause a lot of damage. Usually they just clang around the drum until the wash ends and they are pulled out. But sometimes these objects, particularly the sharper ones, wedge themselves through the drum perforations and damage the machine's internal components.

Sharp objects can puncture the door seal, which can cause leaks. The tank that holds the drum might be exposed to repeated impacts from foreign objects that could cause water leakage and require you to replace the washer drum. The tank can be so expensive to replace that it's usually more affordable just to replace the washer. Small objects can also block the drainage system, which will cause the drum to remain full of water. If this happens, you should unplug the machine and inspect the drain and filter.

Worn-out shock absorbers cause a banging sound

The tub of your front-loading washer is stabilized by shock absorbers, and since these parts receive a lot of kinetic energy, it's common for them to go bad. These struts use spring-like motion, often assisted by hydraulic fluid, to reduce vibrations while the machine is running. You can find these parts at the corners of the tub, linking to its frame. When the absorbers wear out, you will hear a banging sound, as the tub rattles against its frame. The machine will also shake more than usual, which can cause damage to other parts. That's why it's important to fix this issue as quickly as possible.

Call a technician and have them disconnect the machine from its power and remove the rear panel. Upon closer inspection, they might see internal fluid leaks, indicating that the shock absorbers had gone bad. They will then have to use a socket to remove the plastic pins that hold the shocks in place, then replace them with the new ones.

Damaged suspension springs might also cause a banging sound

In most top-loading washers, the tub is stabilized by suspension springs or rods that attach between the cabinet frame and the outer tub. These springs absorb movement and help keep the tub centered during spin cycles. Many models use four springs—one at each corner—but some designs use three or more depending on the washer's size and manufacturer. Like shock absorbers, they absorb a lot of the vibrations from the drum as it spins, preventing it from making too much noise. When one or more of the springs is broken, you'll notice clanging or banging noises as the drum pitches back and forth.

A technician will unplug the machine and disconnect it from the water to begin the repair, then remove the machine's cabinet (its metal exterior) by unscrewing it from the back and sliding it off. One or more springs may even have slipped off, in which case, try reattaching them using your hands. The technician will remove the springs and then attach your new springs, applying a little bit of grease to their hooks to reduce friction.

Loose spider arms cause a rumbling

The spider arms are sometimes known as the drum spiders or the basket spiders because they support the inner drum, where you place your laundry. Its three arms hold the drum and it connects to the motor, which spins it. In some cases, one of the arms will corrode and break, leaving the drum unbalanced. This will result in very loud clattering noises as the drum rumbles against the inside of the washer, which can damage other washer components and even wear a hole into the tub. That's why the moment you suspect a spider arm has broken, you should stop the machine and call in a technician.

Spider arms often experience galvanic corrosion because they are made of tin, which forms an electrical reaction with the stainless steel drum and soapy water. A technician usually needs to repair loose spider arms because you have to deconstruct the entire machine. They will unplug the machine and disconnect its water supply. Next, they'll have to remove the washer's back panel and unscrew the bolt that secures the rotor. They will detach the wire harness, the mounting bolts, and the rotor positioning sensor from the stator. Then they will remove the stator and separate the outer tub halves to access the spider arms. The next step is to attach the new spider arm, firmly bolting it in place. After that, they can reassemble the machine.