15 Genius Tips To Drill Holes Into Metal

Sometimes life tests us, and this could come in the form of the need to drill holes into metals of all kinds. You are probably already thinking of a million things that could go wrong with this arduous task. We get it; drilling holes into wood or concrete is cake compared to this. That is why we have got your back. There are a plethora of reasons why you would want to drill a hole into metal — perhaps you're working on creative projects or doing some garage renovations.

Let's dive into the helpful tips to drill holes into metals, no matter what kind of project you're working on. And for this task, we recommend that you check out the hacks on drill bit sizing posted to House Digest previously. Metals are distinct from whatever it is you have worked with before, whether it was wood, bricks, or cement, so this extensive guide is perfect for working with metal instead.

Protect yourself first

When working with metal, your safety could be compromised in so many ways. However, when drilling metal, you are mostly at the risk of getting injured by stray shrapnel. So, before you get into your DIY, Industrial Metal Supply recommends that you get safety glasses or safety goggles. Other important safety gear could be overalls for your body, cut-resistant gloves to protect your hands, and boots for your feet. Cover yourself up, and you will be glad you did!

Hold the metal to your work surface with clamps

Working with metal would require multiple drilling processes and multiple tools. So, to ensure you have a safe space for work and to prevent any form of accident, it is prudent to purchase and employ clamps, writes WikiHow. Also, by using metal clamps, you prevent the metal or steel from slipping away from your work's surface. This prevents you from making extra scratches and which could be a ready source of frustration, and we do not want that.

Determine the kind of hole you want to drill

Consider what type of hole you are trying to drill and why. Are you following instructions on how to set up a new chair, bed, or an expensive futon couch? The required holes, which will be different for each task, also determine what kind of drill you need for the task ahead. According to Ask The Builder, the kind of metal you're working with also determines how to drill your hole. Thus, if you are working with, let us say, a ⅜ inch hole, your go-to technique is first a pilot hole.

Choose the right kind of drill

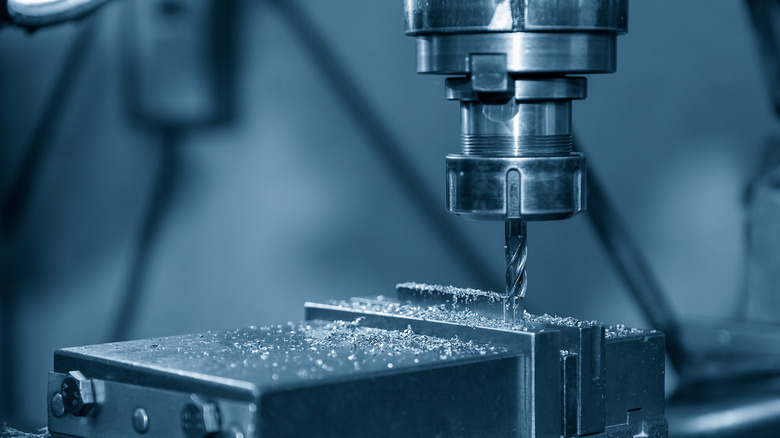

Contrary to the rumors you may have heard, you can drill holes into metals using any kind of drill. The difference, however, is that you have to be extra meticulous about the kind of drill bits you use. You can read up on our distinctions between cordless drills, impact drivers, and hammer drills.

To drill holes into metal, you want to choose drill bits that have an enlarged center and are twisted. This has more grip and is sure to get the job done, says Cordless Drill Guide.

Mark the holes you want to drill

Another way to get your job done really fast is to measure your metal work materials and mark your hole points. You can do this with a sharp pencil, chalk, a little bit of spray paint, or just anything that can mark a spot. Alexander from Welding Mastermind says that marking your intended work spot simply helps you achieve precision and helps you do excellent work.

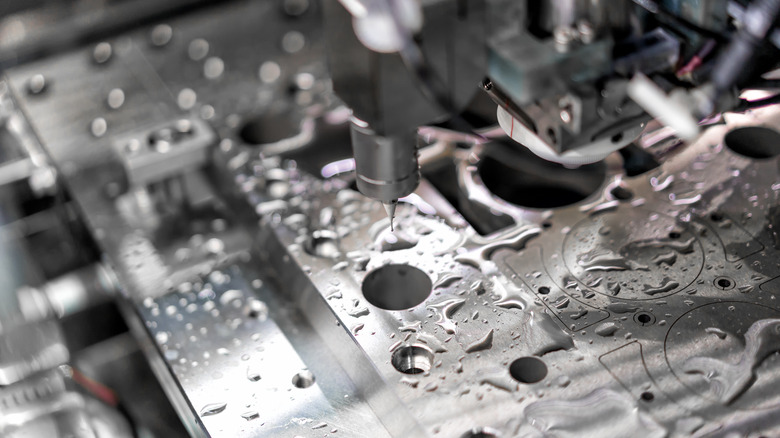

Make a pilot hole first

The benefits of a pilot hole cannot be overemphasized whether you are working with wood, plastic, or concrete. When trying to drill metal, your drill bit might be slippery and not exactly stay on the first try. To circumvent this problem, making a pilot hole first by using a good old nail and hammer helps you get an indentation. Once you have your indent, place your drill right in it and drill your desired hole in your piece of metal, writes Tim from Ask the Builder.

Drill slowly with low rpm

Since metal is much harder than wood or plastic, you may be tempted to drill fast because you think it will get the job done faster. Well, please throw that idea away because not only is it inefficient, but it is also dangerous; if there is any slip, you'll sustain the most injuries. Movie Cultists write that steel is better off being drilled at a slow but steady pace. And Ask the Builder warns against high speed because it increases friction and heat. We do not want that.

Get a drill press for thicker metal piece

Drilling metal does not have to require a lot of physical energy. If the metal is thick and you need a really deep hole, you may want to purchase your drill press or find one in a nearby workshop. Whatever it is you do, ensure you work with one because it ensures your work has more precision, says Dake. To work with this, simply insert your drill bit into the drill press into the section that opens up whenever you fiddle with the chuck, writes Instructables Workshop.

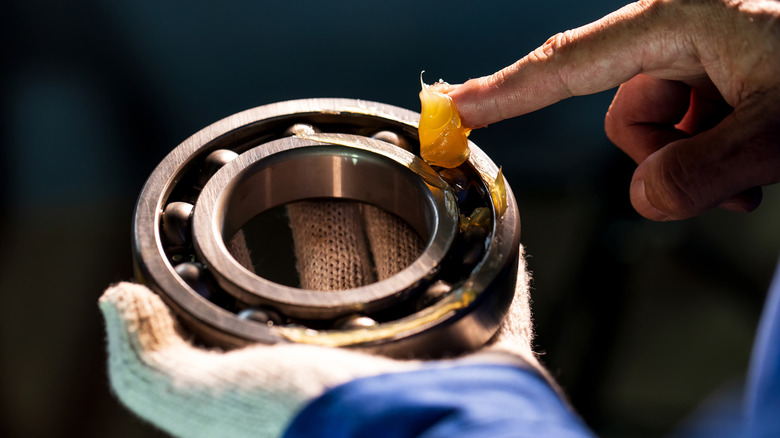

Work with a lubricant or bid farewell to your drill

As you probably already know, metals are hard nuts to crack, so your drill may require special tips. Black + Decker recommends that when working with your drills and especially when your workpiece is metal, using lubricants is a tested and trusted way to ensure that they last their intended shelf life even if they do not extend the more. Also, The Ruko Blog writes that using lubricants helps reduce the chafing between the drill bits and the work object (metal).

Use cutting oil for your steel

If you are familiar with cutting metal, you would be aware of the intense friction and heat that can build up in a crazy short period. And quite frankly, between the workpiece metal, your drilling tool, your drill bits, and you, you would sustain the most injuries. So we and TTP Hard Drill Bits recommend that you purchase either a cutting paste or cutting oil to help you cool the metal, ease and hasten up the drilling process and prevent injuries to you and your tool.

You could always employ a hole saw

We wish hole saws could do little jobs; if they could, the hole saws would have been the one-off go-to tool for cutting holes through metal. But it's not, so we gotta move on. If you need a large diameter hole through any metal piece, the hole saw was designed for just that, writes Plumber. Also, this tool is great at enlarging pre-existing metal holes rather than cutting out new ones.

Cool your workpiece at intervals

Since heat build-up from the friction is unavoidable, best practices require that you cool your metal at intervals. While you could always do this with cooling oil or cooling paste, as we discussed above, you could also take to drilling at intervals, especially if the metal is rather thick. TTP Hard Drill Bits writes that you shouldn't drill for more than 30 seconds at a go. So what you want to do is to drill for 30 seconds, cool for 30 seconds, rinse and repeat.

Use a metal rasp to smoothen the hole

After drilling your hole, to achieve perfection or that professional look, or just to get rid of sharp edges, employ a metal rasp. Metal rasps, also called trims or files, are used to smooth out and shape metal. Bob Villa writes that you should place the metal rasp or file with its teeth against the work area and work it back and forth till you achieve your desired smoothness.

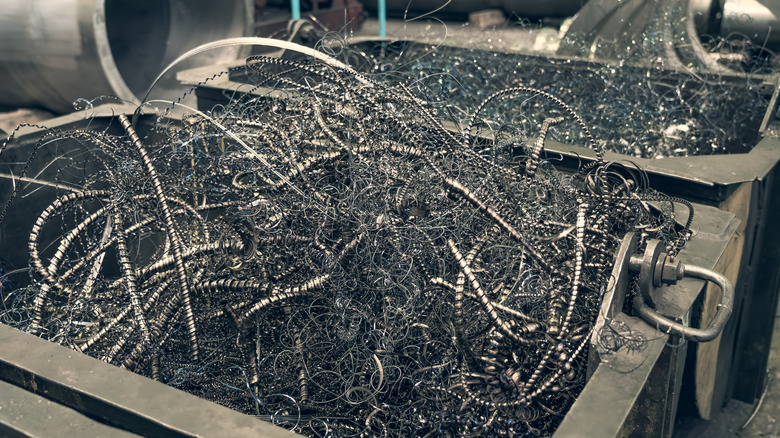

Clean all the shrapnel

Once done with the drilling process, unclamp the workpiece, place it on a nearby table to cool, and clean your tools and put them away. You'll have a lot of metal shavings that could be sharp and potentially dangerous, and you'll want to clean them up pst haste. Today's Homeowner says that all you simply need to do is place a piece of the magnet into a thin polythene bag and hover the bag around your workspace till it attracts all the shavings. Once done, turn the nylon bag inward and throw it in a bin.

Lubricate your ready-to-use metal

For the final touch to your newly drilled metal, lubricate the new hole and overall workpiece. There are a plethora of options to choose from. The DIY Life says you could always use a silicone spray. We love this because it gives protection against water and reduces the chances of rust. Furthermore, you could always mix up some home lubricants. Make writes that all that is needed is that your solution is a mix of 90% vegetable oil and 10% acetone.