The Most High-Demand Household Items That Sold Out In 2022

During the height of the pandemic, many household items were out of stock, including toilet paper, disinfecting wipes, soap, sanitizer, and others. While there are some residual shortages from the pandemic, most of those items are back in stock. Still, two and a half years later, many others are out of stock or in short supply. CBS News explains three factors — availability of raw materials, logistics, and labor — have to be in balance. If any are out of balance, there could be supply chain issues.

Professor of operations at Northwestern University Kellogg School of Management, Achal Bassamboo, told CBS: "If any part of the supply chain is disrupted because crops are not coming through, parts are not in stock or trucks are not available, that leads to disruption, which means supply chains will have shortages." Many current shortages are due to supply chain issues, including manufacturing closures, shipping delays, and labor shortages. Prices are also up due to the double whammy of inflation and supply and demand.

"Those systemic problems in the supply chains, this has been building for years," Steve Dowse, senior vice president and general manager for international solutions at FourKites, told The New York Times. "The pandemic has really just highlighted the fragility of our supply chains."

Building supplies are still in short supply

The lack of building supplies is a challenge for the building industry and would-be new homeowners. After two years of growth, demand to build new homes is slowing this year, reports CNBC. According to The Associated General Contractors of America (AGC), 93% of the 602 members surveyed reported experiencing material shortages this year. For example, the waterproofing foam used for stucco lath is in short supply this year (via Supply Chain Dive). During the pandemic, lumber was also in demand, but The National Association of Home Builders reported sawmills were slow to react to consumer and retailer demand for lumber. Now prices are up due to supply chain problems — last year's wildfires in the U.S. and Canada, and market volatility from doubled taxes on lumber imported from Canada.

According to Construction Dive, the Russian invasion of Ukraine is also impacting the supply chain and causing rising prices for items, including copper and aluminum, of which Russia is a top producer. Erin Roberts, Ernst & Young's global construction and engineering practice lead, told the supply chain publication, "It's as bad as any time during COVID. You've got all this demand after a brief pause shutting down the supply chain, and it's just causing havoc."

Aluminum cans aren't easy to obtain

Aluminum has many uses around the house, including in food and drink cans, deodorant containers, electronics, silverware, siding, car parts, bike frames, aluminum foil, and more, as per Metal Men Recycling. But lately, it's been in short supply. As CBS News Miami reports, breweries are having a tough time getting cans for their beer, and when they get the cans, they're paying a lot more than usual. "When we order aluminum cans, $5,000, $7,000, $10,000 that has to be spent because the cans are available in that moment," S27 brewery co-founder Lucas Szymanowski told the news channel.

Britannica says aluminum is the most abundant metallic element on earth. It's found worldwide, including in India, China, France, and others, and is smelted from its raw state. It can be recycled again and again, and that scrap metal can be turned into more aluminum items, such as cans. Demand for aluminum has been high. The Aluminum Association's preliminary estimates indicate a 6.6% demand growth in the U.S. and Canada in the first half of this year, which is on top of last year's 8% increase.

The increased demand is happening for a few reasons, including breweries distributing beer in cans, which are stackable and lighter than bottles. Add this to the fact that during the pandemic, American consumers enjoyed canned drinks and food at home, and there are more canned hard sodas on the market, and you get yourself a shortage (via Shanghai Metals Market).

Pet food is in higher demand

Pet food has been harder to find this year, especially canned dog and cat food, which are typically packaged in aluminum cans — items that have been in short supply recently. In a USA Today article, the Pet Food Institute attributed the shortages to transportation and labor problems, as well as higher demand for pet food as pet owners have been feeding their cats and dogs more and offering more treats during the pandemic. Downtown Tabby Pet Store says an increase in pet adoptions over the past few years has also resulted in higher demand for pet food. Plus, they say many pet food manufacturing facilities had to shut down during COVID-19, and that ripple effect from temporary closures is still being felt.

"Food brands are promising they are going to get better in the next four and six months; others are saying it might be up to a year before we see some of their products back in stock," Steven George, general manager at Pet Stuff in Minnetonka, Minnesota, told KSTP. "It really is kind of a wave of one week it's ten brands, other weeks it may be one brand that has a shortage, so it really depends on a weekly basis."

HVAC supplies are dwindling

If you're waiting for parts to repair your air conditioner or for a new unit to be installed, you're not alone. "One of my salespeople was talking to a supplier; they told him 42 to 46 weeks before we would be able to get a piece of equipment," Ben Dominguez, president of Oasis Air and Solar, told KBAK in Bakersfield, California. "That's been the norm, everybody's been saying 6 to 8 months to 10 months, now it's looking even worse than that..."

According to HVAC Informed, supply chain issues are affecting the availability of HVAC components, including shortages of copper, aluminum, steel, semiconductor chips, and plastic. Labor shortages are also having an impact. Still, demand is up as more consumers these days want air conditioning, especially those working from home. Hotter temperatures over prolonged periods have also been driving the need and demand for A.C. To prevent A.C. unit problems, do regular maintenance.

Paper has been challenging to source

Sure, most of us write digitally on computers and smartphones, but we still use a lot of paper, including post-it notes, books, journals, magazines, product labels, and more. Still, it's surprising to know there's a global paper shortage. Printing Impressions (PI), which tracks the printing industry, says it's been challenging to source paper. Tonya Spiers, president of Knight Abbey Printing and Direct Mail in Biloxi, Mississippi, told PI, "We cannot hardly get any uncoated stock, envelopes, and now coated sheets are becoming an issue. I have been told the reason why is due to paper mills on strike; plants shutting down; and the lack of mill employees, [truck] drivers, and shipping containers."

Office supply company PaperStone says another reason for the paper shortage is increased demand from consumers who want to be more sustainable — using paper instead of plastic for packaging. Market Realist says office and school supplies have been in short supply this year, which has been made worse now post-pandemic, as more office workers are returning to the office and students are heading back to school. The paper shortage is expected to linger a while until the paper supply chain can stabilize.

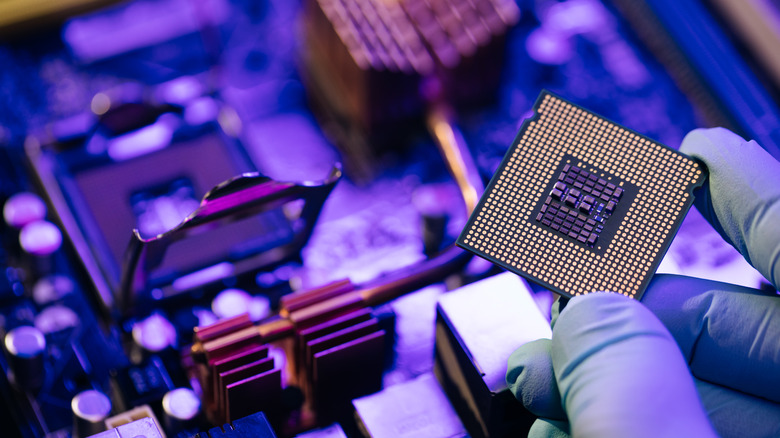

Chips are in low supply

The chip shortage has nothing to do with snack food. Instead, think about the chips powering your smartphone, cars, home appliances, and other technology. The semiconductor chip industry is expected to be worth $600 billion this year, according to Deloitte's 2022 semiconductor industry outlook. They say one missing chip can halt the sale of tens of thousands of dollars. Their analysis estimates the chip shortage during the pandemic cost lost revenue globally of more than $500 billion. The company gives two main reasons for the shortage: More technology companies are adding more chips to their designs every year, and more products have more chips than in previous years. Two examples they cite: smart tags on boxes and connected devices in consumers' homes.

Another complicating factor is potential supply chain problems due to the conflict between Russia and Ukraine. CNBC reports the two countries are the largest exporters of the gas krypton, which is used to make chips. Ukraine also produces half of the world's neon, which is used for chip-making and lasers (via CNBC). Vinay Gupta, the International Data Corporation's Asia-Pacific research director, told CNBC, "The semiconductor supply is not going to increase immediately. There are a lot of raw materials, gases, which were required for production of those semiconductors." The chip shortage and supply chain issues are expected to improve, but Deloitte says the problems could linger into next year.

Garage doors are hard to source

Earlier this year, The New York Times reported a shortage of garage doors. The publication breaks down the shortage, saying supply chain issues are to blame. They say essential materials for constructing garage doors, such as steel, spray foam insulation, and polyurethane, are challenging to get right now for many reasons, including labor shortages, closed warehouses, and international import issues. Added challenges? During the pandemic, there was an increase in new construction, resulting in more demand for garage doors and other housing staples. Plus, many people remodeled their homes during the past two years, including getting new garage doors.

The supply chain problems are expected to linger. In the meantime, consumers can expect to pay more for the garage doors they order. "We've seen the raw material side prices double and triple, which then trickles down to the consumer," John Hamon III, owner of Hamon Overhead Door in Paso Robles, California, told KSBY.

Exercise gear is in high demand

You'd think exercise gear would be back in stock two years after everyone started working out at home due to the quarantine and closure of gyms. Things are slowly improving, but there still are significant shortages. Bicycling reports that the bike shortage that started in 2020 is still ongoing. The supply chain is a big problem now, as well as labor shortages and logistical issues. But a lack of components keeps higher-end bikes off the trails and roads. Prices and wait times are increasing too.

"Chains, cassettes, brake pads, tires, and drivetrain kits are also a big wait," Derek Fetko, co-owner of On Your Left Cycles in Louisville, Kentucky, told Bicycling, explaining wait time for a new bike can be six to 18 months. "I'd say it's actually gotten worse [as the pandemic has progressed]."

Garage Gym Reviews (GGR) compared general availability and price changes before, during, and after the pandemic for some of the most popular items on their site. This includes wearable tech, exercise bikes, weight benches, dumbbells and barbells, and treadmills. They found increased demand for fitness gear and limited supply, especially since more people have a home gym. For example, GGR says adjustable kettle balls were completely out of stock during the early days of the pandemic but were back to full availability by July 2020. Then, a few months later, the inventory dropped to 11%. Nowadays, half the supply is available. Plus, they've seen increased fitness equipment prices, which they expect to continue.

Distilled water flies off the shelves

According to Rocky Mountain Water Distillers, the distilled water shortage has been ongoing since 2017 but has worsened during the pandemic. They say it's been in short supply for a few reasons: increased demand, plastic bottle shortages to bottle the water, a slowdown in the supply chain, and labor shortages. Distilled water has many uses around the house, including humidifiers and irons, CPAP machines, and home aquariums. It has no bacteria or minerals and can prevent buildup in these devices (via Verywell Health). It's also used for watering plants.

Be cautious about substituting another kind of water. That's because distilled water isn't like regular tap or bottled water. MY9NJ says it's made by collecting the steam from boiled water until that steam becomes liquid again. Their reporting detailed how difficult it's been to buy distilled water. For example, CVS stores and a Shoprite grocery store in New Jersey had no distilled water in inventory. While distilled water typically sells for $1 to $2, the TV station's search on Amazon showed prices over $15 for similar bottles.

There's a global rubber shortage

There's a global rubber shortage, and you're probably noticing it. News4Jax reports that some consumers in Jacksonville, Florida, are waiting a month or longer for tires for their cars. Disposable rubber gloves, used for everything from cleaning your house to protective gear for medical providers, are in demand, too, and that increased demand is resulting in higher prices.

The Market Realist explains that the worldwide shortage of natural rubber, which is made from latex tree sap, is the result of supply chain issues like clogged ports and container shortages in Southeast Asia, where 90% of natural rubber is produced. Gallagher Fluid Seals says a poor crop due to leaf disease and flooding is also to blame. Last year, Katrina Cornish, an Ohio State University professor, predicted the problem, telling CNBC, "We could be on the cusp of a rubber apocalypse."