BX Cables: What To Know Before You Buy

"BX cable" is the sort of term most homeowners will only hear about in passing. "What you have in there is BX cable," a contractor might say, "so you need all new wiring, plumbing, and a new roof." When you try to look it up, it appears to refer to at least a couple of completely different things. And if you ask for help, 17 licensed electricians will immediately tell you that you're going to burn down your house unless you stop asking questions and hire a professional.

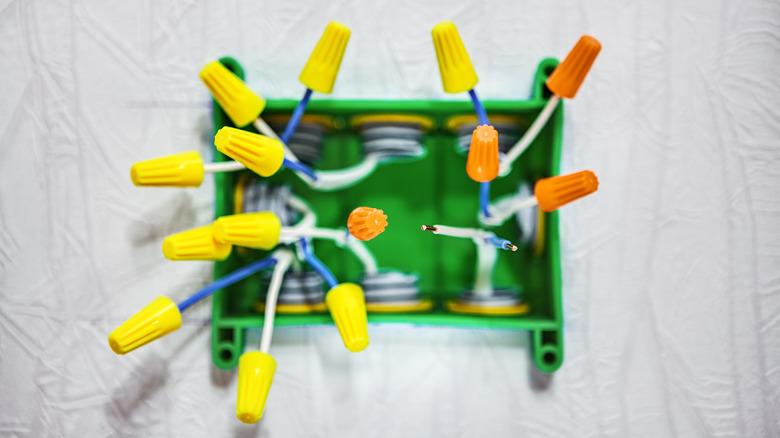

To understand any cable, including BX, the first step is knowing what a cable is in the first place, and where better to look for definitions than a dictionary? Warshauer Electric Supply hosts a very thorough lexicon of electrical industry jargon and slang, from which you learn that electricians are a colorful lot and that they seem to have a tenuous grasp on human anatomy. You also learn that a cable is "two or more insulated conductors wrapped in metal or plastic sheathing." (Note that it can also include a grounding conductor that might not be individually insulated.) Think of a cable as a group of more than one wire. To get a handle on all of this, it's important to know that modern BX cable is a term used interchangeably with AC (armor-clad) cable. Older BX cable is substantially different from the new stuff, and is no longer allowed by code, and this is the source of yet more confusion — but we'll get to that later.

Confusion about definitions

Even Warshauer seems confused about BX cable, defining it as a flexible, armor-jacketed cable with a Mylar wrap covering all the wires and eliminating the need for anti-short bushings. Other sources, including manufacturers, say the wrap is a water-resistant, fire-retardant paper (via AFC Cable Systems and Southwire), and more importantly Warshauer's definition omits the most commonly cited defining characteristic of BX cable: It doesn't contain a ground wire, because the metal jacket itself is bonded to an integral wire, and the combination is meant to be used as a grounding conductor. Also, BX manufacturer AFC and the National Electrical Manufacturers Association (NEMA) agree that anti-short bushings are required for BX cable.

A definition offered by industry professionals like Warshauer that gets almost every aspect wrong is not an auspicious start to understanding BX cable or anything else, but it illustrates the point that such matters are very technical, and if you don't hire a pro, you're going to burn down your house (or at least fail an inspection). In fact, very few resources we looked at got all the details right, and because the National Electrical Code doesn't specifically name or define BX cable, it's difficult to adjudicate all the confusion with absolute certainty.

WesBell Electronics, for example, basically says AC, BX, and MC are all equivalent. This matters because MC cable can be used outdoors in certain circumstances, but BX/AC never can be, contrary to many online sources. If a credible company like WesBell, which has sold wire and cable to its customers for 34 years, gets some details wrong, how can a layman hope to get a handle on it? And this is just one example. As we said, almost no one gets all the details about BX cable right.

BX vs. MC cable

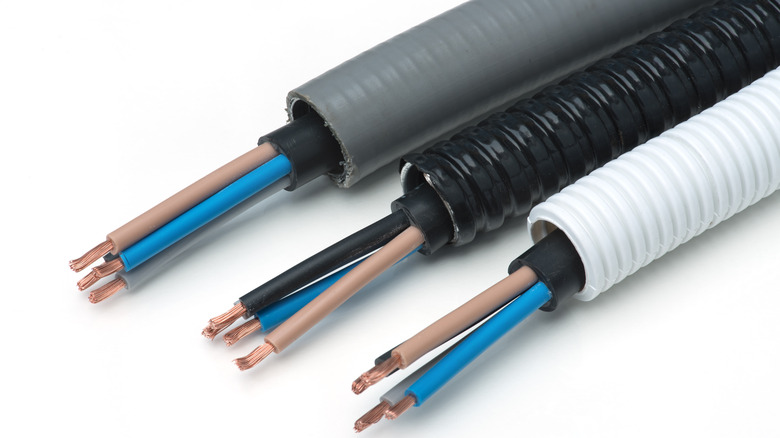

It might help to go back to the basics. Understanding all electrical cables starts with understanding Romex, a brand name of Southwire that is often used to stand for common nonmetallic (NM) electrical cable. The weaknesses of Romex — namely, its lack of protection against damage and environmental factors — are the positive attributes of metal-armored cable. Whereas Romex is easy to both install and cut or puncture, armored cables are more difficult to use, specifically because they provide their wires more protection.

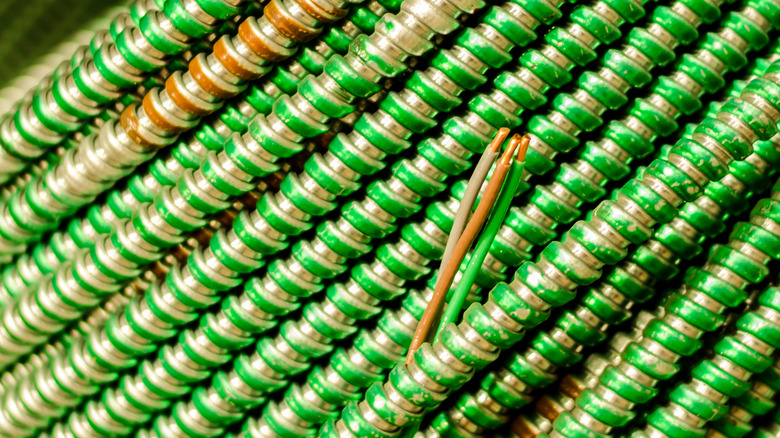

You can think of BX cable as a type of metal-clad (MC) cable in which a kraft paper wrap (via AFC Cable Systems) protects the conductors from shorting on the armor, and which can, but doesn't always, contain a separate ground wire (because of the integral bonding wire mentioned above). MC cable uses its metal armor only for mechanical protection from damage. BX can carry an additional insulated ground wire inside the sheathing, but this is usually used in applications that require redundancy, as in medical facilities.

So, the key differences between BX and MC cable are the use of the armor as a ground path, the material used as protective sheathing, and the fact that MC can — when specified for damp locations — be used outdoors, but BX/AC cannot. One final distinction is that MC cables don't have a limited number of conductors they can contain, while AC cable can contain no more than four insulated conductors. What MC and BX have in common is their basic armored structure, which means that its individual conductors are better protected than NM and similar cable. Both are sometimes simpler to install that wire in conduits, which reduces the cost. BX cable can, by some estimates, be 35-40% more expensive than NM (via Healthy Building Science), yet still be cheaper to install overall.

Cables similar to (and confused with) BX cable

For a layman, the varieties and names of electrical installation cables can be mind-numbing right out of the gate. As we've said, AC and BX cable are the same thing, but that's only true when referring to modern BX. Older styles of BX lacked an internal bonding strip that improved the use of the metal jacket as a grounding conductor, and are not compliant with modern electrical codes, according to Electrical Contractor. North Central Washington Home Inspections explains that AX and BX were early prototypes ("X" standing for "experimental"), of which BX was successfully produced for trade use. Modern AC (BX) and MC cables have many sub-types, further exacerbating the confusing tangle of acronyms and initialisms. Depending on the manufacturer, you'll sometimes see "-90" or "lite" appended to the product name, generally indicating the particular metal with which they're clad: steel for "-90" and aluminum for "lite."

A lot of brand names are involved, but there are a few standard initialisms in the industry that are used by the two main manufacturers of MC and AC cable. For example, MC-PCS cable can include a power control signal on a separate wire, often for controlling lighting. MC IG cable is designed to carry multiple insulated ground wires, useful for when separate, isolated, or redundant ground paths are required, such as when supplying power to medical equipment. In fact, health care facility equipment accounts for a lot of the special-use cables. These are usually postfixed with "HCF," as in AC-HCF or MC-PCS HCF (via Atkore). Interestingly, one AFC-brand cable labeled MCI-A (and its healthcare version, MCI-Stat) uses the cable armor as a ground path, previously something that only AC/BX cable did. There are some physical differences aimed at efficient installation, but, functionally, this erases a lot of the distinction between AC and MC cable.

Why you may need BX cable

As you might have noted from the special applications in the previous section, BX is primarily used for commercial, industrial, and multi-branch residential circuits. BX is also occasionally used for standard single-family homes. AFC Cable Systems describes a number of applications, the most common of which might be exposed and surface-mounted installations. Because the cable is armored, it has enough protection from the usual hazards (toddlers, mountain bikes, throwing knives) that it can be mounted outside of your walls rather than within. This obviously makes retrofitting your bonus room to include electric throwing knife targets much easier. The usual caveat applies, though: "Exposed" doesn't mean "exposed to the weather." Keep your AC/BX cable indoors.

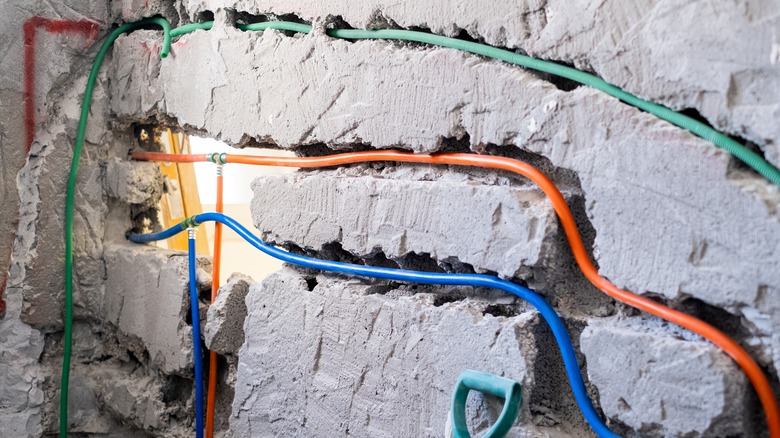

BX can also be embedded in plaster on masonry and run in the air voids of masonry walls, under raised floors, and in air-handling spaces. You might see raised floors, for example, in churches or data centers. And, again, take note that these allowances don't apply if any of those spaces are prone to getting wet.

BX cable is, naturally, rodent-resistant, so if your home is in the country and therefore prone to mice — or if your spouse keeps beavers as pets — you might consider the protection of BX cable. And if your spouse has all but stopped practicing knife-throwing or hanging out with beavers because of unusually high EMF readings, it's worth noting that BX cable reduces both magnetic fields and electrical fields normally created by home wiring systems, whereas MC cable only protects against magnetic fields (via Healthy Building Science). These same properties might make BX beneficial for use by audiophiles, as well.

Why you may not need BX cable at all

MC cable overlaps a lot with BX in terms of permitted uses. Uses that are not permitted are ultimately summarized in National Electrical Code 330.12(1): "Where subject to physical damage." This is a common theme in the NEC: Don't do things that will compromise the integrity of the cable, or it could otherwise lead to fire or electrocution.

Compared with MC cable, BX is less flexible in applications permitted by electrical code. Some varieties of MC cable can be used outdoors or even "direct-buried" — that is, buried underground without need for conduit — whereas BX cable cannot be used outdoors at all (via Nassau National Cable). BX requires anti-short bushings, while MC doesn't, though master electrician and founder of Electrician U, Dustin Stelzer, finds this distinction "bizarre" given that the two cables are structurally almost the same, and have the same issues that would require a bushing. Finally, AC cable is limited to four conductors, while MC is not limited.

What all of this means is that MC cable is more flexible and easier to use. It now comes in varieties that use the armor as a ground path, and varieties that include multiple grounding conductors for redundant applications and other purposes. Anywhere NM cable is not allowed, or must be run through conduit, some version of MC cable can be used, and this is not true of AC. So, at least for residential use, it is not clear that there are any cases in which BX/AC is preferable to MC.

The problems with old-style BX cable

The very mention of "BX" produces alarm in the eyes and heart of many older electricians and home inspectors, because early versions of BX were deeply flawed. Those flaws have been corrected in the modern product, which is allowed by the NEC as AC cable, while old-style BX is not. According to JP McCurdy Electrical Services, a lot of the negativity surrounding BX cable comes from both the shortcomings of the old-style cable and the misuse or misunderstanding of the cable in the first place. An example of this is the use of the grounding conductor (and therefore the armor itself) as a neutral conductor rather than a ground — an inexpressibly dangerous mistake. McCurdy says that the insulation, wraps, anti-short bushings, bonding wire, and galvanizing process of the early BX cable have all been improved and are as safe today as other approved cables.

Early BX, on the other hand, can be hazardous. For example, the earliest versions didn't include a bonding wire (they used only the armor for a ground path), so its armor could get dangerously hot in a fault condition. The reason for this seems a little arcane, but is actually straightforward enough. Metal armor is spiraled around the wires within. You calculate its properties as a conductor by stretching it out to its uncoiled (and much greater) full length, because the interlocking edges aren't considered a strong enough electrical link. Given the resistance of the steel used in early BX cable, this effectively means you are using a ground wire that isn't of sufficient capacity, as if using a 16- or 18-gauge ground wire for 12-gauge conductors — a clear no-no throughout the industry.

Pros and cons of BX

BX cable shares a lot of characteristics (and, therefore, many pros and cons) with MC cable, as well as many restrictions of use with NM cables like Romex. BX cable is armored, and that obviously improves its resistance to puncture by nails and screws. Assuming its bend radius is observed carefully, an NEC-compliant install of BX is unlikely to be damaged during normal use. It can be purchased in spools and pulled directly without the added labor of cutting, bending, and installing conduit, and can be used in areas where conduit is not allowed or is not practical, according to JP McCurdy. BX can be installed in exposed interior locations, and it can include additional insulated grounding conductors, making it useful in healthcare and other situations where redundancy is required. Finally, BX provides superior shielding of electrical fields and equal shielding of magnetic fields compared with MC cable, which is useful where very sensitive electronic equipment is involved or, hypothetically, if someone has health concerns about exposure to electrical fields (via Healthy Building Science).

The unique downsides of BX are that it cannot be used in wet, damp, or exterior locations, and obviously it cannot therefore be direct-buried or used as aerial cable. It turns out there are versions of MC that share all of the potential major pros of BX and none of the cons (via North Central Washington Home Inspections). That just leaves matters of installation and cost.

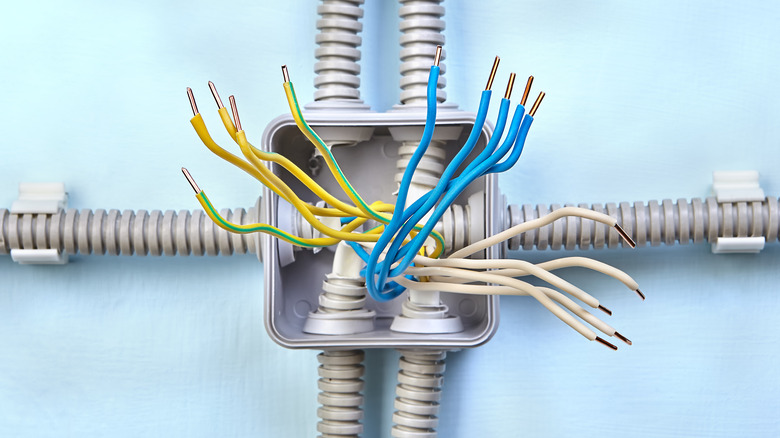

How BX cable is installed

Cable manufacturer Southwire claims BX can reduce installation costs by 50%, as compared to conduit and wire. This is a major advantage for BX, but the savings probably mostly apply to MC cable as well. Let's have a look at the installation process. Typical residential MC and AC installations start after wall-framing with careful planning and layout, beginning with home-runs from the load center (circuit breaker box), says the National Armored Cable Manufacturers Association. The average residential installation is basically similar to standard Romex, except that obviously the support fittings, connectors, etc. are different. Cable may be routed through wall studs and certain dry structural spaces, such as within masonry air space gaps. MC cable must be supported every 4.5 feet and AC every 6 feet, except in a few special circumstances. Both cables may be cut in a number of ways, though the use of a standard rotary cutter makes for the cleanest edges, which is important in all cases and critical for using anti-short bushings as required for AC cable (and sensible for MC cable as well, via WikiHow).

Termination varies by cable sub-type, but, in general, the processes for AC and MC are basically the same, except that MC will have a grounding conductor that must be terminated properly at each electrical box, adding 50% more wire terminations per box. Keeping expensive AC and MC variants like AC-HCF and MCI-A out of the picture (since they mostly apply to commercial and industrial settings), this means that there will be some minor increase in labor cost associated with installing MC versus AC cable.

Average cost of BX

Because of the difficulty in making a fair apples-to-apples comparison, homeowners understandably struggle with unpuzzling cost comparisons when electrical cable is involved. At Home Depot, 250 feet of Southwire 12/2 solid copper, aluminum-armored BX cable costs $198, while the same MC cable costs $199. Wholesale prices aren't readily available for Southwire BX and MC, but the Atkore pricing difference is less than $8 for MC versus BX cable.

Southwire's MCAP product, a metal-clad cable which uses its armor for grounding, is $238 for the same specs at Home Depot. Southwire offers a calculator to demonstrate the supposed labor savings that justify the simpler installation of MCAP versus standard MC wire, which involves one fewer termination per electrical box. Assuming a home uses 10 circuits (via D&F Liquidators) and 10 outlets, plus another five terminations for switches and light fixtures (via REthority), the calculator estimates $625 in savings for all 150 termination points. Since MCAP terminates similarly to BX, we can use that figure as a general reference for comparing MC to BX/AC cable.

There are many other ways to look at the question of BX cable's comparative cost-effectiveness, including factoring in the potential use of NM, the cost of fittings required for BX, etc. Steel Tube Institute did a rather tortured analysis of commercial costs of EMT conduit versus MC cable, attempting to demonstrate that the long-term total cost of ownership of conduit is less than for metal-clad cable, even considering higher initial costs. Your mileage may vary and, in fact, almost certainly will.