Oil Vs. Water-Based Polyurethane: What's The Difference?

Most of us would agree: woodworking is an art. Any DIYer who's ever worked with wood has likely encountered the issue of what type of finish to use. Wood needs some sort of finish, per Fine Woodworking. The finish serves a few important purposes, such as protecting the surface from the elements and everyday wear. It also improves the aesthetics of the wood itself, bringing out the natural grain and preserving its beauty. Once the finish is applied, the wood surface will remain cleaner and easier to protect. Depending on what the finish is being applied to, however, different finishes may be recommended, with the appropriate level of protection.

Another purpose of finish has to do with wood's inherent nature of absorbing moisture, and its vulnerability to seasonal expansion and contraction. Certain types of finishes are helpful in reducing this but don't necessarily make wood waterproof. So what's the best kind of wood finish? Unfortunately, there's no one-size-fits-all answer. Generally speaking, however, polyurethane is considered to be one of the best choices in wood finishes. Let's take a look at what polyurethane is, and compare oil vs. water-based polyurethane. We'll find out what the differences are, and which kind is best for your particular project.

What is polyurethane?

According to The Home Depot, polyurethane is a strong, durable clear coating suitable for a range of wood finishes. To understand what polyurethane is, it's important to understand the chemistry. On a microscopic level, the resins in polyurethane bond together to form a tight seal as it dries. But there are different types of polyurethane, and it comes in different forms and in multiple products, via Polyurethanes. It's technically made from plastic polymers and can be flexible or rigid in solid form, and in its liquid form, can be either water or oil-based. In its more solid forms, polyurethane is also used as insulation, cushioning in furniture and mattresses, car parts, adhesives, shoe soles, and much more!

For wood finishes and other DIY projects, you can choose from semi-gloss, gloss, or satin. Also, there's now a water-based, oil-modified urethane (per Kray Custom Refinish). It's versatile, and this substance is in products we use every day. As a wood finish, polyurethane is considered the top choice of woodworking professionals.

Now that we know a little bit about what it is, let's talk about some of the differences between water- and oil-based polyurethane finish.

Quality and appearance differences

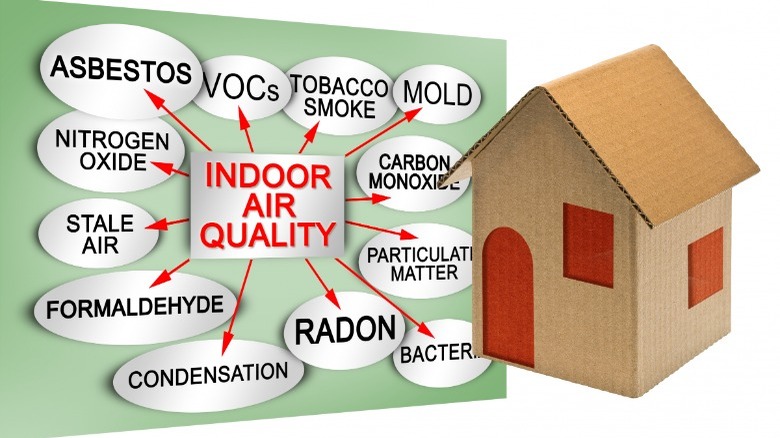

When finishing or refinishing wood, which type is best really depends on what you want to finish, and how you want it to look afterward (via Angela Marie Made). Oil-based polyurethane has a slight amber tone to it, so it will give wood a different look than water-based. Sometimes people use oil-based poly when they want to make something look slightly aged. Oil-based poly dries hard and is durable and strong after applying a few coats. However, keep in mind that the volatile organic compounds or VOCs are higher in oil-based polyurethane, which is why they've now formulated an oil-modified water-based polyurethane (via Kray Custom Refinish). This kind also has an amber tint when it dries, even though it first appears cloudy. But it has lower VOCs like water-based poly.

On the other hand, water-based poly is a clear-drying finish used when you want to preserve the wood's natural color and bring out the grain. Water-based polyurethane also has a cloudy appearance when wet, but it dries perfectly clear. No color is added to the wood with this finish, but since it's thinner, more coats are needed. It can be cleaned up easily, but keep in mind you should never use any product with ammonia on a water-based polyurethane finish. Also, water-based polyurethane is less likely to crack over time, and is easier to clean up. Oil-based can become brittle and yellow with age.

Application and drying time differences

There are definitely some differences in application and drying time between oil and water-based polyurethane (via Wood Magazine). For one thing, if using oil-based, you'll want to dilute it by about 10% with mineral spirits, helping to thin the liquid and produce a better brush flow. Water-based poly does not need to be thinned. You can use either a foam or a natural bristle brush with oil-based poly. With both kinds, you will need to sand in between coats, especially after the first one. While drying, you'll need to choose a dust-free location and wipe the surface clean often.

The other main difference is with drying time, and as previously mentioned, the number of coats you apply. According to Resin-Expert, water-based is ready for a second coat after 8 hours, while oil-based needs 24 hours. Water-based is dry to the touch after 24 hours, but oil-based needs 48 hours. You can put objects on top of the water-based surface after two days, but wait four days for oil-based. When it comes to the complete curing time of the two, water-based polyurethane wins again at 20 days, while oil-based versions are cured after about a month. Additionally, don't place any rubber mats on them for at least a month, or you'll have marks on the surface.

Durability and maintenance differences

According to Brothers Home Improvement, when placing furniture on wood floors after finishing, be sure to put felt on the bottom of every spot where it touches the floor. All table and chair legs should have a piece of felt glued or nailed and glued to the bottom so they don't scratch the finish. Cleaning polyurethane in general should be done by dust mopping, and no harsh cleaners should be used. If any film is left on the surface, when it comes time for refinishing or re-coating, it will not be able to accept the finish. Vacuuming and dust-mopping are typically all you need to do for regular maintenance.

According to Resin-Expert, water-based poly is safer due to its low or even no VOC content, plus it has no strong odor like oil-based poly does. Water-based polyurethane is considered to be a less durable finish but keeps better clarity over time. Oil-based polyurethane is a stronger and more durable finish due to its thickness as well as the oil base, but turns yellowish and can break over time. As we've mentioned a few times already, the oil-based poly has a higher level of VOCs, so perhaps we should discuss just exactly what that means, in terms of safety.

Safety differences

The main problem with polyurethane finish is the harmful fumes, per Ecos Paints. It contains known toxins called isocyanates that can be unsafe due to respiratory concerns. There are many health risks associated with the VOCs we've been talking about here, which is why water-based polyurethane is a far safer choice. But for either choice, the longer it's allowed to dry or cure, the fewer VOCs are emitted.

Additionally, the better ventilation the room has, the safer it will be. Open the windows when finishing or refinishing floors or any wood surfaces, and use water-based polyurethane whenever possible. No matter how you look at it, lower VOCs equal a safer product overall. Respiratory problems like asthma can occur or worsen, especially if the product is not allowed sufficient time to cure, and fumes can cause nausea and headaches as well.

Still, it is important to recognize the potential harm and choose your product wisely. Isocyanates are also harmful to the environment, so you might want to select an eco-friendly product, much easier to find in water-based polyurethane (via WoodInto). Not only that, but water-based polyurethane finishes its off-gassing process within a few days, while oil-based polyurethane can give off gas for months or even years! The fumes from polyurethane in general are typically gone from the home within two to five days, which is good news since the actual fumes are considered the most harmful.

Advantages and disadvantages of oil-based polyurethane

According to Angela Marie Made, oil-based polyurethane is best for darker-colored woods, deepening the amber tone. You shouldn't use it on any painted surface, but it is good for bringing out deep brown hues of natural wood. It's also easier to apply, per Kray Custom Refinish. Oil-modified urethane products are also recommended due to the easier application process, faster drying time, and lower odor. You'll basically want to use oil-based when you want to use a darker natural wood color to make it a richer, deeper tone and want the increased durability and scratch-resistance of this type of finish.

Only apply oil-based polyurethane outdoors or in an extremely well-ventilated area, and make sure you have mineral spirits on hand for thinning as well as cleanup. Waste from this product is considered hazardous, so dispose of it properly. Be sure to only use oil-based poly when you have time to allow each coat to fully dry, and no one else is exposed to the potentially harmful fumes. Some people really prefer the amber tone and finish of oil-based polyurethane, so a big part of it is personal preference, as well.

Advantages and disadvantages of water-based polyurethane

Water-based polyurethane is typically your best choice, up to 90% of the time, per Target Coatings. According to this source, if you purchase a well-made product, the durability is as good as oil-based. Use water-based poly when you want to preserve the color of the wood and do not want any yellowing with age, as it will intensify over time. Water-based dries two to three times faster, but for every coat of oil-based poly you'll need to use at least two coats of water-based. You can apply as many coats of water-based as you like, but oil-based has a tendency to scratch and chip after two to three coats.

Additionally, water-based poly has a distinct advantage previously unmentioned. It adheres to almost any surface very well, like oil-based, but oil-based polyurethane does not bond well to itself, meaning you'll have to sand again after each coat to create a secure bond. Not so with water-based poly! Another great advantage is that due to its inherent solvents, you can work with water-based poly for a longer duration than with oil-based. Lastly, as we've already noted, water-based polyurethane is much safer to use and is less harmful to the environment.

Satin vs. semi-gloss: What sheen is best?

Now that we have a better handle on oil vs. water-based polyurethane, let's talk about sheen. These products are also made with different sheens, per On Woodworking Art. Let's briefly cover the two most popular types, starting with satin, the most popular. This sheen is preferred by many homeowners particularly for wood flooring because it has a nice luster that doesn't accentuate imperfections. It's easy to maintain and versatile to use on many different surfaces with no concerns about slipping. However, it's less durable than semi-gloss, and scratches tend to show up more.

Semi-gloss polyurethane finish runs a close second and has a higher sheen than satin with a higher level of protection. It's more expensive and slightly more difficult to maintain. Using semi-gloss polyurethane finish provides a shinier, cleaner-looking surface, but isn't recommended for households with kids or pets, and works best in low-traffic areas. Mostly this is due to showing dents and marks clearly. For these reasons, semi-gloss polyurethane finish is recommended more for wood trims or cabinets, over floors.

Though less popular, gloss and matte finishes are also available. Gloss polyurethane finish, of course, provides a very high shine and is used mostly in commercial settings. In fact, it's used for bowling alleys and on gym floors, and has a high risk of slippage. It's highly resistant to stains and water, is very durable, and is easy to clean. However, it's not suited for wood floors in the home. Matte finish is good for walls and ceilings and makes it easy to hide imperfections. But it's not very durable and it's difficult to clean.

Cost differences and product improvements

There are definite differences in prices, and for those, we look at Cost Owl. For oil-based polyurethane finish on wood floors, you're going to pay anywhere between $20 and $40 per gallon, and you can cover about 400 square feet with one gallon of product. On the flip side, water-based polyurethane finish is going to cost you between $40 and $80 per gallon, but you can cover 600 square feet with this option. Since we've covered many pros and cons of each of these products, it mostly comes down to which one has the qualities most important to you and your project.

Many people find the safety concerns about using oil-based polyurethane to be enough that they don't want to use it. With potential harm to themselves as well as the environment, this is completely understandable. However, you still may want to use an oil-based poly for varying reasons, so be sure to check out the new modified products on the market today. Not only that, but technology is always advancing faster than consumers can keep track of, and there are many different new products that boast features that nullify the problems of others.

For example, according to Art News, Rust-Oleum has an oil-based polyurethane triple-thick finish for interior or exterior surfaces that provides waterproofing and UV protection. It's considered a varnish that, when cured, has the flexibility to expand and contract with seasonal movement. It's perfect for boats, outdoor furniture, garage doors, and more, and has a fast drying time that allows another coat in just one hour. Of course, it's going to depend on what you want to use it for, but it's important to note there are a ton of polyurethane finish products out there. So good luck, and choose wisely!