DIY Projects Are A Whole Lot Easier With This Must-Have Saw Accessory

We may receive a commission on purchases made from links.

Circular saws are great as they can cut through any wood. But, while they are designed for cutting straight lines, they do a fairly poor job of cutting straight with any precision. It's often difficult to see where the saw blade meets the material, and there's no built-in mechanism to keep the saw blade from wandering as it cuts. If you set your saw to cut unnecessarily deep, as many do, the blade can work against you getting your cut back on track. Enter the SkateGuide and SkatePlate, the solution to much of the friction keeping you from cutting in a straight line.

It's easy to become confused about exactly what this product is and which saws it fits, so let's nail that down. The SkateGuide ($37.95) is a cutting guide, or rip fence, for circular saws that attaches to the saw itself and can be adjusted to cut various widths (up to 13 inches for the standard SkateGuide and 27 inches for the SkateGuide-Zilla). It won't fit many circular saws and is also sold as part of the SkatePlate, which includes a shoe into which both your saw and the SkateGuide fit. A guide on the SkatePlate website shows which models it will fit. It comes in varieties for blade-left and blade-right saws but uses confusing terminology. A "sidewinder" saw has its blade on the right when you're cutting, and a "worm-drive" saw has its blade on the left, corresponding to the Sidewinder and Worm Drive SkatePlate models.

What the SkatePlate and SkateGuide do for you

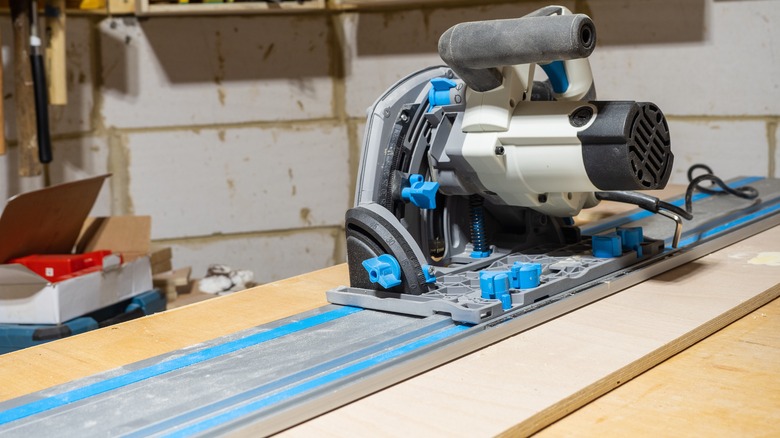

The plate part of the SkatePlate system – the part that the saw clamps into, effectively replacing its built-in shoe — is designed to reduce friction with the material you're cutting. It does this with two long polyurethane rollers at the front and back of the shoe that eliminates the shoe's contact with your workpiece, reducing friction and helping keep the saw going in a straight line.

But the main function of the SkatePlate shoe is to make sure the SkateGuide rip fence fits your saw, and the fence is where the rubber meets the road in this setup. The fence rides along the edge of the board you're cutting and (assuming the edge is straight) cuts a parallel straight line at whatever width you set it to, up to 13 or 27 inches depending on which model you have. Rollers in the fence are designed to make the process go more smoothly, though some reviewers report that they can complicate the beginning or end of a cut if only one roller is engaged. One rolling pivot point is obviously not very effective as a fence. Note that the SkateGuides sold separately have 10 closely spaced rollers, while the ones that come with the SkatePlate only have four. The majority of complaints from Amazon reviewers, though, are about the shoe not fitting their particular saw. The online fitment guide is thorough but isn't mentioned in either SkatePlate listing on Amazon.

How the SkatePlate stacks up against alternatives

The idea of a circular saw rip fence is nothing new. Many saws include a slot for attaching a rip fence. Model-specific fences are available for many saws, as are universal fences. Some circular saws even come with a rip fence. These typically don't have the rollers or handles like the SkateGuide fence ... and don't require the SkatePlate to fit whichever models they're designed for.

If your goal is repeating the same cut again and again, and your workpiece has a straight edge, saw-attached rip fences are ideal because you can set them up once and cut many times. If you are just looking for a clean, straight line, there are approaches that might be easier in some circumstances. Clamp-down fences and tracks from Kreg and others are common, and you always have the option of a full-blown plunge track saw like the Makita plunge saw and guide rail, $519 at Home Depot or the famously expensive Festool track saws (the TS 75 is $975 at Amazon). All of these devices must be positioned for each cut, but they don't require you to have a straight edge on your material. And you can always cut against a clamped straight edge, assuming that you're sure it's straight, that it's as long as the material you're cutting and thick enough to properly engage with your saw's shoe, and that you always follow woodworking safety precautions when using any saw for your project.