We Used Dryer Sheets To Deal With Sawdust In Our Workshop And Our Eyes Thanked Us

You know how a face shield can make your woodworking less safe? When you can't see out of the thing. Woodworkers sometimes eschew personal safety gear a little too easily, and this is especially true of eye protection and face shields. They tend to be uncomfortable and they get fogged up easily. But, perhaps worst of all, they seem to attract sawdust better than your dust collection system. I recently caught wind of a trick that's supposed to help with this, involving using a fabric softener sheet to make face shields resist this accumulation of sawdust. I thought it was worth a try, and I wondered if the sheets can also help with removing sawdust in general.

I once tested a hack to make painting plastic easier using fabric softener sheets. It seemed promising, and the science behind it seemed sound (as far as I can tell as a non-scientician). But none of that seemed to apply to dust avoidance and removal. Is it possible that dryer sheets have two more tricks up their soft, static-free sleeves?

All we need is dust in the wind. And dryer sheets.

I wanted to test the sawdust rejection notion on both a face shield and a standard pair of safety glasses, as I'm much more likely to use safety goggles in the workshop and other important places it's easy to forget about. There is a lot of anecdotal evidence online that the dryer sheet hack works for both. All I needed was dryer sheets, the safety equipment, and a source of sawdust that can be flung at the safety equipment. Thankfully, there's no lack of sawdust or sawdust-producing machines in my workshop. Routers are better at producing sawdust, but nothing flings the stuff as uniformly as a miter saw.

For measurement equipment, I decided to go with my eyes — I'd just look through the glasses and face shield after each test and note what I saw. There might be a better way to tell if a pair of safety glasses is easy to see through, but there's not a more important or intuitive way.

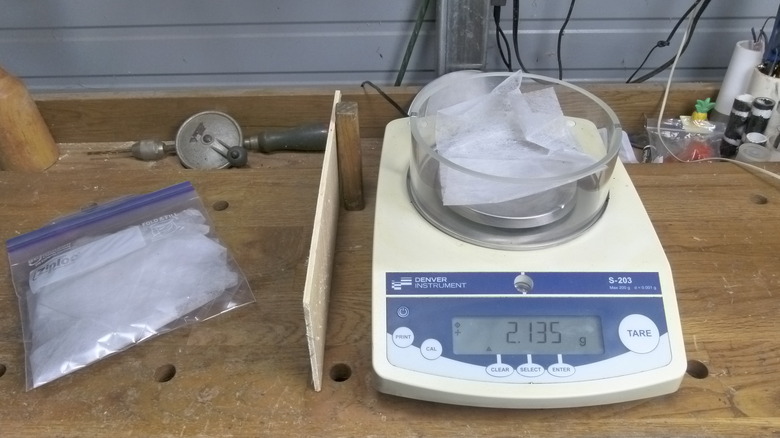

Testing sawdust removal is a little more complicated. I'd obviously need something to compare it with — terry and microfiber cloths, for example. The tricky part would be deciding if it worked. To this end, I devised a slightly over-engineered and under-effective experiment involving a very precise scale, a box of sawdust, an air compressor, some bits of scrap underlayment, and the aforementioned rags and dryer sheets.

Should dust stay or should it go?

While I was researching this dryer sheet hack, I came across a number of users on woodworking forums claiming that you're better off using used dryer sheets rather than new ones for managing sawdust in the shop. Some speculate that new sheets can leave gunk behind on any surface they touch, thereby actually increasing the likelihood that stray sawdust will stick to them. So I tested both ways, cleaning with denatured alcohol between each trial. I went about it in the most lo-fi way possible: the face shield and glasses were placed behind a miter saw's dust exhaust port. The glasses were affixed to a backdrop to keep them in the line of fire. I then sawed through a scrap of untreated SPF 2x4 four times and examined the results.

For the dusting portion, I weighed each rag (one each of White Rags-brand shop paper towel, microfiber cloth, and dryer sheet, all sized to match the dryer sheet). I added 50g of sawdust to a piece of underlayment, let fall away whatever dust insisted on falling away, then wiped the board once in each cardinal direction with one of the cloths. I then weighed the cloths to determine how much dust they managed to collect. The boards (one for each cleaning cloth) were thoroughly cleaned with compressed air between each test and the dryer sheet was used last in case it left any residue behind.

Another one fights the dust

The odd thing about these tests is that I'm asking the fabric softener sheet to do two opposite things: repel sawdust from clear polycarbonate, while attracting sawdust to the sheet itself. One purpose of fabric softener sheets is eliminating static electricity from laundry, so the use on face shields seems logical and more likely. Dryer sheets are used to keep things dust-free, particularly electronics, by eliminating static electricity on the surface of the object being dusted. But wood is very nearly neutral in terms of its tendency toward a positive or negative electrical charge, and therefore unlikely to collect much in the way of static electricity. I had no way of knowing how the dusting test would go.

The safety gear hack did well. The items treated with used dryer sheets attracted about ¼ of the sawdust of the untreated glasses and shield, and the new dryer sheets performed even better, but left a slightly smeary residue behind. That was definitely a win. The dusting capacity of dryer sheets was less impressive. Paper towel and microfiber swatches picked up more dust, while the dryer sheet barely collected any at all. Since the main reason I remove dust in a workshop is to prep a surface for finishing, I'd hesitate to rub on a bunch of fabric softener residue before applying the finish. Not a win for dusting, but the earlier win was so huge, and dusting alternatives are so numerous, that I didn't really care.