3D Printed Homes Styles That Have Us Excited For The Future

The future is here and as surreal as it may sound, architects now have the ability to 3D print their blueprints and construct full buildings with the use of modern robotics. 3D printing sounds like a new concept, but this system's first prototype was invented back in the 1980s. Over the past few decades, the initial printing model has been innovated and altered to perform faster, cheaper, and larger projects. Engineers have optimized industrial-sized 3D printers to build homes in a matter of days, sometimes under 24 hours. Various companies have collaborated in the design and construction of these projects; many of them focused on robotic technology, sustainability, and solving housing crises around the world.

This futuristic process may be a newer invention, but it already has many benefits over traditional construction methods. 3D printing is more affordable, efficient, eco-friendly, and versatile than building homes by hand and using conventional machinery. Learn more below about revolutionary 3D building projects around the world and how these projects can shape the future of architecture and country-wide housing issues for the better.

The first US 3D printed home in Austin, Texas

The very first 3D printed home in the United States was a prototype unveiled in Austin, Texas, in March 2018. A team of designers, engineers, and environmentalists from Icon, a start-up 3D robotics company, and New Story, a non-profit dedicated to ending homelessness, collaborated to create this 350-square foot prototype home, which they penned "Chicon House." The purpose of this construction was to show how 3D printing can build shelters for the homeless while saving money and time.

The project took a total of 47 hours over multiple days, resulting in a modest two-bedroom, one-bathroom, and single-kitchen abode. An outdoor porch surrounds the entire concrete and wood construction, and the exterior is decorated with industrial-style chairs and assorted succulents. The interior displays a boho-farmhouse vibe with its Aztec-style rugs and pillows, animal-skin rugs, and bold colors, and it looks no different than homes built using traditional construction methods. Throughout the house are operational lighting fixtures, showing how even prototype 3D homes can have aesthetically-pleasing interiors and utilize modern amenities. The engineers and designers behind this home intend to print more copies of this well-received prototype for homeless families in El Salvador and other communities in the future.

The largest 3D printed home of 2020 in Calverton, New York

3D printing endeavors started strong at the beginning of 2020 when the largest 3D printed home to date was revealed in Calverton, New York. SQ4D, A robotics-focused construction company, was proud to announce their 1,900 square-foot demo home with three bedrooms and one bathroom in late January. It took only 48 hours to print over the span of eight days, and it cost less than $6,000 in materials to complete. The time it took to print the first model of this home is expected to decrease as SQ4D continues to improve and enhance their Autonomous Robotic Construction System (ARCS) 3D printing systems.

This home is remarkable not only for its size but for its appearance, which imitates traditional housing. The single-story design with a wide floorplan defines it as ranch style, and there is an attached one-car garage. The company intends to make more homes in this familiar design, placing them up for sale in nearby neighborhoods throughout New York and surrounding areas.

The first 3D printed house certified for occupancy in Riverhead, New York

SQ4D is responsible for more than the largest 3D printed home of its time; they are also the masterminds behind the first 3D printed home listed for sale in the United States. Using their ARCS technology, they crafted a building with a certificate occupancy that was also listed on a Multiple Listing Services (MLS) for real estate— if you've never heard of it, you should know MLS is a real estate technology used to optimize transactions for legitimate real estate properties. This home was based on the previously-mentioned building made by ARCS, and it is over 1,400 square feet with three bedrooms and two bathrooms.

The house is made entirely of concrete, but its exterior is modeled to look like gray wood siding. It has another familiar architectural style, though the company modeled this version after traditional Craftsman homes instead of ranch-style. The low-pitched roof, covered front porch, and shingles are expertly crafted to attract potential buyers to an innovative building that doesn't appear too far out of the ordinary. This home is now off the market, as its listing was removed back in January 2022.

The zero-net energy 3D printed home in Desert Hot Springs, California

Mighty Buildings is a company founded in 2017 that focuses on creating beautiful and sustainable modern 3D printed homes. One of their most remarkable builds is "The Mighty Quatro," which is a modern prefab-style home stretching an impressive 1,176 square feet. This home is for sale and ships to empty lots throughout California, where it can be hooked up to electricity and plumbing connections for occupancy.

The house is valued under one million dollars, which some people may find unexpectedly low for something built by innovative robotic systems and state-of-the-art equipment. Despite the low price, it has all the amenities you would expect in a modern build. Worth noting is the fully-equipped kitchen with a full-sized refrigerator, custom cabinetry, a four-burner stovetop, dishwasher, and convection oven and microwave, and the luxurious bathroom with quartz countertops, a walk-in shower, and laundry appliances. In addition to these various amenities, The Mighty Quatro is commendable for its sustainable foundation and exterior.

The exterior composite wall panels are made from a concrete alternative that is stronger but lighter than traditional concrete. Mighty Buildings also claims that it has a robotic coating that resists hurricane winds, high water, fire, mold, insects, and extreme temperatures. The "Mighty Kit System" installed on the home produces only 1% of the waste generated by traditional homes due to these materials and solar panels, which makes the home even more self-sufficient.

The Lego-like 3D printed homes in Coachella, California

Coachella Valley in California is on its way to becoming the world's first neighborhood of self-sustainable 3D printed homes. Mighty Buildings, the same company that built "The Mighty Quatro," is currently working on a collection of 15 homes in white modular designs to make up a five-acre neighborhood. Each home is 1,450 square feet with three bedrooms, two bathrooms, and a swimming pool on a 10,000-square-foot property. These gorgeous, self-sustainable homes will sell for under $600,000, making them highly affordable for their size, quality, and location.

The homes are made from a stone composite material, the concrete alternative resistant to fire, moisture, and pests. What makes this construction reminiscent of life-size lego blocks is how they are assembled. The interior and exterior walls are snapped together in a similar fashion to the popular child's toy. Just like this company's other zero-net energy build, these homes will be topped with solar panels to produce energy for the lucky individuals that reserve a spot in this future-esque neighborhood.

These homes have fantastic implications for California, a state notorious for its housing crisis and rising homeless population. 3D printed neighborhoods like this experimental plot in Coachella can pave the way for more affordable and quick construction practices. The Guardian claims California will need between 1.8 million and 3.5 million new units to shelter homeless individuals by 2025, making Mighty Building's future success vital to a spiraling crisis.

The first 3D printed home to be made in one piece in Westerlo, Belgium

The United States isn't the only country making large strides in 3D printed architecture. Kamp-C, a sustainability-focused construction company in Belgium, unveiled the first house to be printed in one piece in the city of Westerlo. This roughly 969-square-foot home was printed using Europe's largest 3D concrete printer, and was made on-site in only three weeks. Kamp-C was very proud to reveal that they built this two-story home, claiming that printing on-site and in one piece can greatly optimize production and reduce construction costs for 3D printers.

The home is notable for its low-energy potential due to the floor and ceiling heating installations, solar panels, and modernized heat pump. The designers behind this build also intend to add a green roof, which is a design built to imitate natural land. Green roofs are complex systems that include waterproofing, root-repellent systems, drainage systems, filter systems, a layer of soil, irrigation methods, and plant life. These roofs add natural beauty to constructed buildings while simultaneously improving energy efficiency.

The first family-owned 3D printed home in Nantes, France

Building 3D prototypes for homes is impressive in itself, but even more awe-inspiring is when these homes can actually house individuals and families. In the United States, you require a "Certificate of Occupancy," which verifies that a building meets fire safety codes, has plumbing and electricity, and functional doors and exits. France requires similar building permits, meaning one had to be obtained for the first family to move into a 3D printed home in the local city of Nantes.

Yhnova is the name of the all-white round-shaped Nantes house, which was inspired by the prototype "BatiPrint 3D". A robotic system built this modern-minimalistic four-bedroom home using two layers of expansive foam and one layer of concrete. It took 54 hours to complete, not including a four-month stint of door and window fittings, and cost 20% cheaper than it would have if built through traditional methods. It is the first home in a social housing project intending to create an entire suburban neighborhood in the same style and using the same techniques.

The unique curved walls aren't only for show— they are designed to improve thermal resistance and air circulation in the home, making it more energy-efficient. These curves also create wider interior spaces, making the layout more wheelchair-accessible. This is an important step forward for mainstreaming inclusive homes for differently-abled people. The curved shapes enabled by 3D printing also made it possible for the designers behind this home to build it around several 100-year-old trees on the property. This eliminated the need for extensive land excavation that would remove valuable natural life from the land.

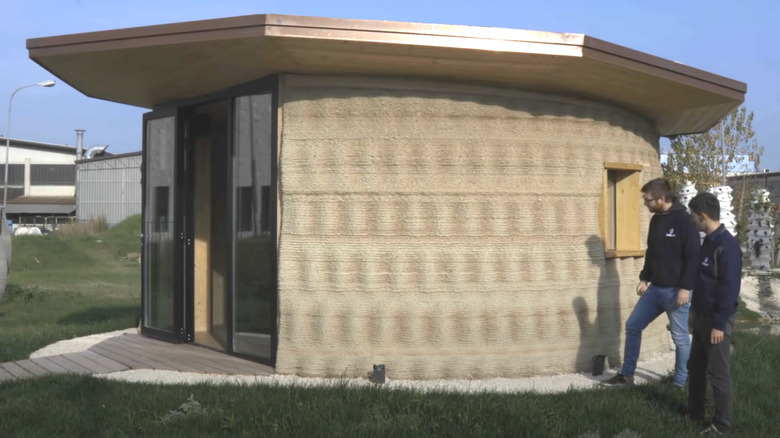

A 3D home printed from biodegradable materials in Masa Lombardo, Italy

It's clear that most 3D printing endeavors focus on sustainability and optimizing production. However, one 3D printed home in Masa Lombardo, Italy, took these ideas a step further by creating a home entirely out of organic materials. This building is known as "Gaia" and was built by WASP to showcase their printer's ability to construct entirely out of soil and agricultural waste.

Gaia is modeled similarly to round Lapa houses found in Africa, and it is completely biodegradable. WASP claims that if the building is not maintained, it will eventually turn back into soil over time since the overall structure is made of 25% soil, 25% rice husk, 40% straw, and 10% hydraulic lime. The engineers behind his project collected most of their materials from an Italian start-up known as Ricehouse, which specializes in building homes from rice collected from local communities and farmers. This home is a great example of how future homes can be built from sustainable materials and support local businesses in the process. Although this demo home is small in size, WASP claims that homes built in a similar fashion can be made much taller and roomier, making them more practical for actual functionality and occupancy.

The self-sustainable 3D printed home in Ukraine

PassiveDom, a Ukrainian company, reached record productivity levels in 2017 when they developed a robot that built a tiny home in only eight hours. The robot prints the floors, walls, and roof, creating a template for a home that requires human labor to finalize the plumbing, electrical systems, and doors. The first and smallest model was dubbed "the modulOne" and is completely self-sustainable in terms of electric, plumbing, and sewage systems.

Solar panels and batteries collect and store energy, an incorporated water system collects water from humidity, and the sewage system runs independently of external connections. In addition to its systems being completely autonomous, this tiny house is made of 100% recyclable materials, including aluminum, carbon, and fiberglass. The interior is modern minimalist with gray wood-style flooring and ceilings, white wall panels, and oversized windows. All interior furniture and cabinetry have a mid-century modern feel with their smooth, curved lines and solid white color. People who are interested in purchasing these homes are even invited for "test-stays" by the manufacturer.

The 3D printed waterfront homes in Ontario, Canada

3D printed neighborhoods aren't only a concept in the United States; Canada's renewable energy and real estate firm, Horizon Legacy Group, plans to build six family homes for under $100 per square foot on a waterfront plot in Ontario. Over 400 individuals have submitted conceptual designs for this community, though Horizon Legacy Group has narrowed their selection down to six finalists. These designers have created blueprints of livable yet aesthetically pleasing 3D housing that also meet Canadian building regulations, making them the perfect fit for this innovative neighborhood.

The extraordinary aspect of this project competition is that it has incorporated the efforts of artists and designers from multiple countries, including the United States, the Czech Republic, the Netherlands, Switzerland, Chile, and Canada itself. Each designer is tasked with meeting certain criteria for constructability, scalability, aesthetics, livability, sustainability, durability, and overall cost to determine which will be used for the primary structure. In addition to driving 3D printed housing developments, this project will also benefit the local community by providing affordable housing to eighteen individuals in the city of Gananoque.

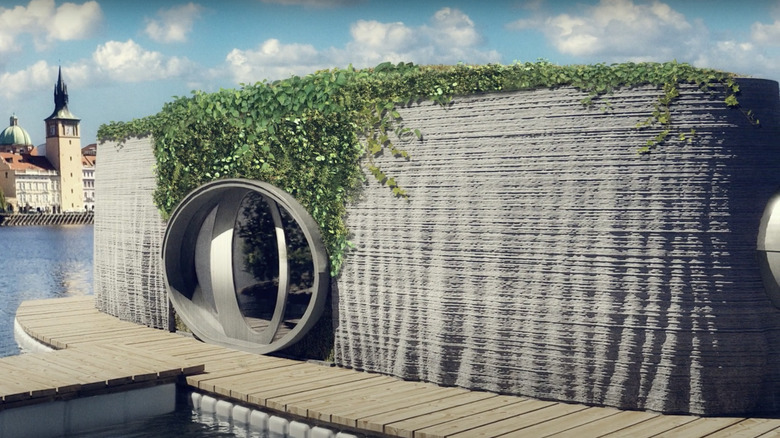

The first 3D printed houseboat in Czech Republic

The first 3D printed floating sculpture with potential for occupancy is the original art piece, Prvok, which has been unveiled in the Czech Republic. In simpler terms, Prvok is a 3D printed houseboat floating on the Vltava River, and it was crafted within 48 hours. The boat is over 450 square feet and has three rooms; a bathroom, kitchen, and bedroom.

This ultra modern houseboat boasts a unique look, having a slim, cylindrical shape and a round entryway. The walls are a concrete mixture of nano-polypropylene fibers, plasticizers, and a setting accelerator, giving them a wavy and textured outward appearance. The roof and part of the entryway are covered in plant life, making the entire build different than any other houseboat design on the market. Prvok's manufacturers expect the boat to last a minimum of 100 years, and they believe future prints will be made in 22 hours at an impressive speed of five inches per second.