We Tried Chapstick To Stop Screws From Splitting Wood And It's The Balm

We've all been there, or somewhere close -– standing on a 14-foot ladder, a mile from your toolbox and 15 miles from a hardware store. You have a board, screws, driver, and nothing to drill a pilot hole with. You get to the last screw and realize you're probably about to split that board. Now that you've actually had the thought, you're certain to. When it splits, your shoulders slump and you wonder where it all went wrong. Early childhood, maybe, or when that thing happened in college. But it most likely went wrong in April when you stopped carrying Chapstick around with you. Because all you really need is a little Chapstick — and a bit of luck — to drive most screws into most boards without splitting the wood.

A pilot hole might be a better bet. The trouble is that every guide to pilot hole bit sizing gives different answers for which one you need for any particular screw. So, you'd end up with an entire library of bits raining down from 14 feet. And the ones for common screw sizes would probably be missing, anyway. There are lots of easy tips for drilling the perfect pilot hole, but most of them require that you have a drill bit. Traditionally, carpenters and woodworkers have hedged against split boards by lubricating their screws under certain circumstances, and rumor has reached us that Chapstick works a treat. So we decided to give it a try.

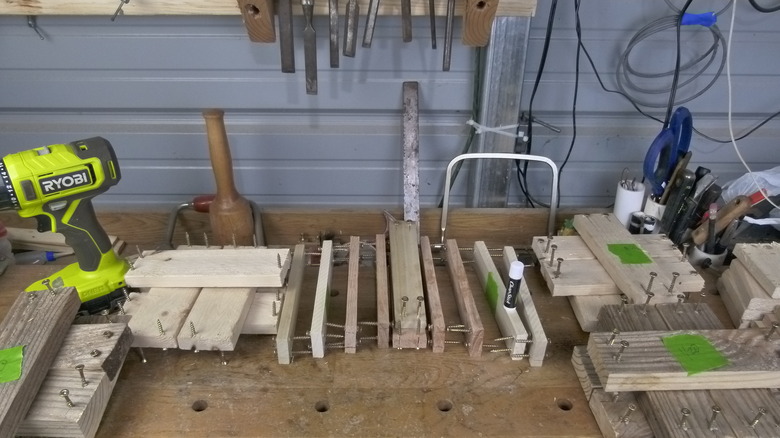

Making scrap from perfectly good boards

When you're driving a screw into it, wood splits more easily if it's too dry, too thin, or too narrow. The wood also tends to split if you're using the wrong screw, sinking the screw too close to the edges, or driving it too deep. Without a pilot hole, your screw is pushing apart the wood's fibers. Softwood (say, pine) is more forgiving, while hardwood tends to split. Keeping this in mind, I made a bunch of eight-inch planks of each material for testing: 10 planks of ¾-inch pine furring; 10 planks of 1-inch rough-sawn pine; five planks of ½-inch poplar; and five planks of ½-inch oak. Each plank received four Grip-Rite #8 x 1-3/4-in Yellow Zinc Interior Wood Screws ($9.48 at Lowe's). Half employed Chapstick; the other half did not.

Chapstick comes in a variety of flavors, and I wasn't sure if it mattered which I used. I live in the country and I've driven "down the mountain" for a lot of things, but lip balm hadn't yet been one of them. So I borrowed a tube from my 15-year-old daughter in Pink Lemonade flavor. This has 13 ingredients in common with Original Chapstick, including apparently relevant ones like petrolatum, paraffin, mineral oil, and carnauba wax, but the original had seven ingredients not found in the pink lemonade, while the pink lemonade had five not in the original... too many differences to ignore. So down the mountain I went for the original.

Driving screws that won't even hold one board together

Whether a board splits when you're driving a screw into it depends, in part, on how far from the end-grain and long-grain edges you're driving it. The closer to an edge, the more likely you'll get a split. So I drove a bunch of screws (sans Chapstick) into samples of each wood species at various distances from the edges, to get a sense of where splits start becoming common when using #8 wood screws. This was generally between ¼ and ½ inch from an end-grain edge. All of the planks were more likely to split the closer to the long-grain edge the screw was, and I marked my planks accordingly.

I lightly coated half the screws with Chapstick and started driving them in using a Ryobi cordless driver, the cheapest drill at Home Depot, which we tested a while back. When switching from Chapstick-coated screws to uncoated, I cleaned my hands with carburetor cleaner to avoid contaminating the uncoated screws; don't try this at home. Full disclosure here: lubricating screws in this way is a practice I've relied on for many years, though not with Chapstick. Over the years, I have used beeswax and even toilet wax seals, which are often made from beeswax or petroleum wax. I figured they were working, but I never tested it. So I expected the Chapstick to do well, particularly given that I wasn't bothering to pre-drill any pilot holes. My bias was, for once, confirmed.

Using Chapstick when driving screws is the balm

The results were decisive, though not staggering. Overall, the uncoated screws were about 17% more likely to split the board. The hardwoods I tested, poplar and oak, were far more likely to split. 95% of the un-balmed screws caused splits (compared to 50% of the pine) and 75% of the screws with Chapstick caused splits (compared to 35% of the softwoods). Because of the way I arrived at the screw location, these numbers are far higher than anything you should experience in everyday woodworking.

Carpenters and woodworkers have used all manner of things to lubricate screws. TikTok recently discovered that the inimitable Paul Sellers has a genius tip for avoiding split boards: paste wax. Others use soap, drawer slide lubricant, spit, and sweat. Some of these lubricants are bad ideas because they tend to draw water to the screws, encouraging rust. But I'm now reasonably sure you can successfully reduce the number of boards you split by applying Chapstick to your screws. Plus, Chapstick is definitely more handy to carry than, say, extremely sticky toilet wax rings. I'd use it because it works, but I'd also use it because it fits in my perpetually overpopulated pockets.