Easy Ways To Extend The Life Of Your Power Tools

Keeping your power tools in top shape is key to making sure your projects don't hit unnecessary snags. Sticking to the manufacturer's guidelines, replacing worn parts, and timely battery maintenance — these simple steps can make a huge difference in how long your tools stick around and how well they perform. Whether you're diving into a DIY home improvement project over the weekend or you're knee-deep in professional construction work, your tools are the heroes of the story. Inside each power tool, a complex symphony of parts works together. From the motor that powers the whole operation to the gears and blades that do the heavy lifting, each component needs to be in top shape for the tool to work efficiently. And overheating? That's a major no-no. It's like running a marathon in a heatwave with no water — eventually, something's going to give.

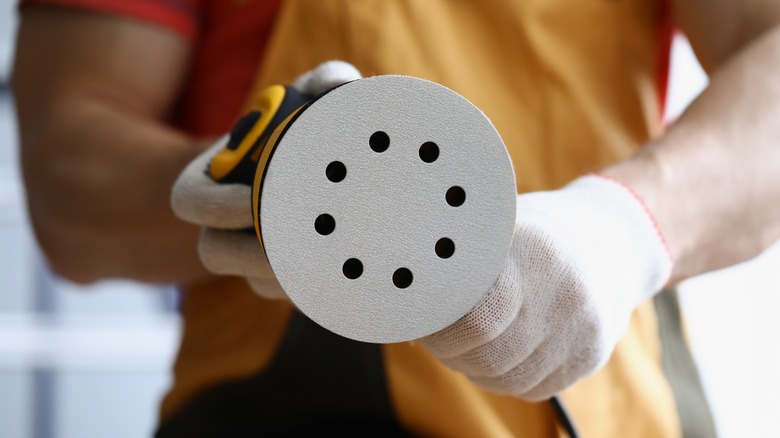

When the tool is well-cared for, it doesn't just last longer; it also works better. Efficiency is where you'll really notice the difference. Think about the smooth cuts from your circular saw, the effortless drilling from your electric drill, or that perfect finish from your sander. Indeed, tools that are cared for perform better, which means you can work faster and with less effort. That being said, it helps to understand exactly what type of care is needed and how to go about it.

Sticking to your manufacturer's recommended service interval

Most power tools come with a handy manufacturer's handbook. It's packed with crucial information about when your tools need a bit of servicing — think of it as preventive care for your gear. Keeping up with these recommended service intervals is your secret weapon for tool longevity. So, what do these service checks really entail? Well, manufacturers lay out a schedule, like a service after every 100 hours of use or annually, to keep things running smoothly. During these checks, a technician gives your tool a thorough inspection. They're on the lookout for any wear and tear that, left unchecked, could lead to bigger headaches. The process includes swapping out parts that have seen better days, ensuring that everything's aligned properly, and giving your tool a good clean-up, especially from the inside, where dust and debris love to hide. For tools that come with software, updates might be part of the deal to keep everything current.

If your tool has any cutting part, you'll want to keep that blade sharp for a clean cut and to reduce the strain. A dull blade can make your tool work harder, leading to overheating and wear. Regular sharpening keeps everything running smoothly and extends the life of both the blade and the tool. Another big part of these service checks is about lubrication. A thorough clean removes any gunk that could hinder performance while proper lubrication ensures that all moving parts glide without friction.

Cool down tools before they overheat

When the intricate parts of power tools get too hot, it's not just a minor inconvenience – that heat can damage these components. If the insulation on the wires melts, it can lead to short circuits or the expansion of metal parts, which can mess with the tool's internal alignment. Over time, this can lead to your tool kicking the bucket way earlier than it should. But what causes this? Overuse is just one factor. Ever noticed how your drill, saw, or sander starts to feel like it's running slow after a long, hard job? That's because, during those intense tasks, your tools are putting in some serious work, and all that action generates heat. Poor ventilation and air quality and the accumulation of dust are two other factors.

Manufacturers know their stuff when it comes to the optimal operating temperatures of their tools. That's why they often include recommendations in the user manuals, like giving your tool a break after a certain amount of continuous use or avoiding pushing the tool harder than it's meant to be pushed. Cooling down your tools after heavy use isn't complicated. Just giving them time to rest and return to a normal temperature can prevent a lot of this heat-related wear and tear, significantly extending the life of your tools and ensuring they're ready and in top shape for the next job. Plus, it keeps you working safely, avoiding the risk of overheating-related accidents.

Replacing worn parts

When you're deep into your work, pushing your power tools to the limit, it's easy to forget that they're not invincible. Over time, parts like blades, bits, belts, and batteries really take a beating. It's the nature of the beast – wear and tear happens, but it's what you do about it that counts. Replacing these worn parts is more than just a maintenance chore; it's a necessity. Think about the blades on your saws or the bits in your drills. They're the business end of your tools, constantly cutting, drilling, or grinding. Over time, they dull or even get damaged. If you've ever tried to push a dull blade through a piece of wood, you know it's not just ineffective; it can be downright dangerous, forcing the tool to work harder and potentially leading to accidents.

Then there are the belts in tools like your sander. A worn belt can slip or snap, which not only messes with your workflow but could also throw off your tool's alignment. And let's not forget about batteries. They're the heart of your cordless tools, but they don't last forever. Regularly checking these parts and replacing them when they show signs of wear keeps your tools running well. This approach doesn't just extend the life of your tools; it also maintains the quality of your work. After all, precision in your projects comes from tools that are in top condition and ready to perform at their best with every use.

Getting tools calibrated

In the world of power tools, precision is important, and calibration makes sure your tools are ready to perform at their best. Think of it as a regular health check-up for your tools, keeping them accurate, reliable, and ready to tackle high-precision tasks at any time. It is also about adjusting your tools so they do exactly what they're supposed to do, just how they're supposed to do it. Imagine you're working on a project where measurements are everything. If your tool is off, even by a little, it can throw everything out of whack. Regular use, wear and tear, and even the environment can lead to what's called calibration drift. This means your once trustworthy tool starts getting a bit off its game, it's like a scale that doesn't zero out.

Calibrating your tools according to the manufacturer's specifications is like hitting the reset button. It ensures your tools measure, cut, or drill with the precision you depend on for high-quality work. This helps maintain the tool's integrity whilst also protecting the quality of your projects. Indeed, accuracy in your work can make the difference between a job well done and one that falls short. Manufacturers often provide guidelines on how and when to calibrate tools. So, it would be best to follow these recommendations during every project.

Maintaining good battery care

Cordless power tools like drills have changed the game, letting you ditch the cord and go wherever the job takes you. But that freedom hinges on one thing — the battery. It's what keeps your drill spinning and your saw cutting. Batteries come in a few different types, including lithium-ion (Li-Ion), nickel-metal hydride (NiMH), and nickel-cadmium (NiCd). NiCd batteries are the old guard; they are tough and tolerant to rough conditions, but occasional use makes them work less. NiMH batteries offer a middle ground with less environmental impact and a better capacity than NiCd, but they don't handle extreme temperatures well. Li-Ion packs a lot of power in a lightweight package, with no memory effect and a longer lifespan.

But here's the thing — batteries don't last forever. Their nemesis? Discharge cycles, heat, and time. Each charge and discharge cycle slowly reduces their capacity until they can't hold a charge anymore. Heat accelerates this decline, while simply sitting unused can cause them to lose charge and eventually fail. To keep your battery going strong, a few practices can make a difference. Don't let them sit fully discharged for too long. And when you charge them, follow the manufacturer's guidelines to avoid overcharging, which can be just as bad as letting them run flat. Store them in a cool, dry place, away from extreme temperatures that can push them to their limits.